Harland Clarke Checks

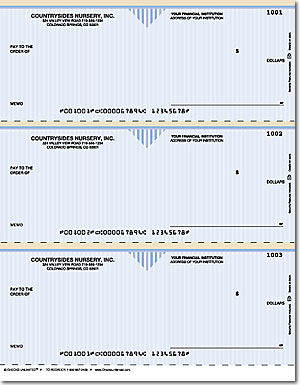

Take Charge of Your Enterprise with a Free Enterprise Checking Account from Centier. Clean laser voucher three per web page checks printed on financial institution permitted 24lb.paper. Our blank test stock makes organizing and managing your small business accounting wants simpler and more economical. Centier’s Free Business Checking can assist you manage your day by day money flow so you’ll be able to consider reaching enterprise success.

Take Charge of Your Enterprise with a Free Enterprise Checking Account from Centier. Clean laser voucher three per web page checks printed on financial institution permitted 24lb.paper. Our blank test stock makes organizing and managing your small business accounting wants simpler and more economical. Centier’s Free Business Checking can assist you manage your day by day money flow so you’ll be able to consider reaching enterprise success.

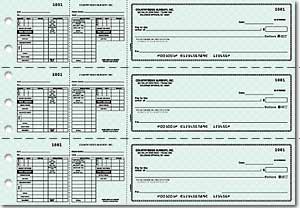

Handbook checks are handy straightforward to use and are available a variety of types. Save money in your Deluxe checks, and get the very best quality there may be. All of our customer support representatives practice for 200 hours on our laser test products and order entry system, giving them a whole understanding of what we provide and methods to reply questions of our prospects.

A super account for small and mid-sized companies with no month-to-month service charges. These are the exact, same checks that I paid four times as much by means of my financial institution. Enjoy the advantages of free online banking, free electronic mail statements and verify safekeeping from the bank you recognize and belief.

Supply – Choose to search your favorite recipe website’s content. We’ve got almost 25 colours of business checks to select – with no additional charge for premium” colors or kinds. We guarantee your checks will meet or exceed business financial institution processing requirements, including Check 21 laws.

The Analyzed Business account receives an earnings credit score to offset some or all of the monthly service charge based on the typical investable balance within the account. Yahoo provides you a wide range of services for little or no price. This account type is best suited for small to mid-size businesses with decrease month-to-month deposits and exercise.…

Select from over 3500 test products. QuickBooks enterprise checks are laser and inkjet printer suitable. This icon is the symbol nationwide for quality checking merchandise. Order checks online from the official Harland Clarke retailer. We’re a member of the Verify Cost Techniques Affiliation (CPSA), the industry’s security and manufacturing society which authorizes to use the security padlock icon on all printed enterprise checks.

Select from over 3500 test products. QuickBooks enterprise checks are laser and inkjet printer suitable. This icon is the symbol nationwide for quality checking merchandise. Order checks online from the official Harland Clarke retailer. We’re a member of the Verify Cost Techniques Affiliation (CPSA), the industry’s security and manufacturing society which authorizes to use the security padlock icon on all printed enterprise checks.

…

…

20 Small Business Ideas within the Philippines for 2018 Manny January 08, 2018 241 Feedback Making a residing in the Philippines may be exhausting in case you are solely trying in a single course, and that’s, employment. Good entrepreneurs now use social networks like Facebook as a cheap and straightforward solution to promote their small companies and attain out to 1000’s of shoppers who would have been invisible and unavailable to them. Pets are exceptionally fashionable within the UK and whereas many are starting to undertake from animal shelters, there may be nonetheless a huge enterprise opportunity for breeding specific breeds of animals.

20 Small Business Ideas within the Philippines for 2018 Manny January 08, 2018 241 Feedback Making a residing in the Philippines may be exhausting in case you are solely trying in a single course, and that’s, employment. Good entrepreneurs now use social networks like Facebook as a cheap and straightforward solution to promote their small companies and attain out to 1000’s of shoppers who would have been invisible and unavailable to them. Pets are exceptionally fashionable within the UK and whereas many are starting to undertake from animal shelters, there may be nonetheless a huge enterprise opportunity for breeding specific breeds of animals.

Do you want to purchase a brand new laptop? Are you sure of what you are looking for? If you don’t, then this is a great place to be! It can be hard to choose from the wide variety of options available these days. Follow the tips from this article so that you can make the best possible choices for your needs.

Do you want to purchase a brand new laptop? Are you sure of what you are looking for? If you don’t, then this is a great place to be! It can be hard to choose from the wide variety of options available these days. Follow the tips from this article so that you can make the best possible choices for your needs. Get ideas for companies to start and for methods to develop your small enterprise with new products and services. If you wish to earn your own money, however are too younger to take a part-time job or would like to be your individual boss, these ideas will enable you get a enterprise began. Housekeeping services for resorts is a proper business concept if an entrepreneur has Rs. 50,000 to start out with.

Get ideas for companies to start and for methods to develop your small enterprise with new products and services. If you wish to earn your own money, however are too younger to take a part-time job or would like to be your individual boss, these ideas will enable you get a enterprise began. Housekeeping services for resorts is a proper business concept if an entrepreneur has Rs. 50,000 to start out with.

Harland Clarke gives private and enterprise checks and check-related products. QuickBooks enterprise checks – order on-line for comfort – come in quite a lot of kinds, colours and unique security features. Ordering normal checks is fast, simple and secure with FAIRWINDS On-line. Order manual enterprise checks from Checks In The Mail.

Harland Clarke gives private and enterprise checks and check-related products. QuickBooks enterprise checks – order on-line for comfort – come in quite a lot of kinds, colours and unique security features. Ordering normal checks is fast, simple and secure with FAIRWINDS On-line. Order manual enterprise checks from Checks In The Mail.

Get ideas for businesses to start out and for tactics to broaden your small enterprise with new services and products. Inform that to the top taskers on the portal who reportedly earn as much as $7000 a month , making this a full-time enterprise idea for some. Write your speech ,” looks as if a compelling business thought to allocate your free time in direction of, belief me—tons of oldsters can pay you to edit admissions essays and offer constructive feedback for his or her children.

Get ideas for businesses to start out and for tactics to broaden your small enterprise with new services and products. Inform that to the top taskers on the portal who reportedly earn as much as $7000 a month , making this a full-time enterprise idea for some. Write your speech ,” looks as if a compelling business thought to allocate your free time in direction of, belief me—tons of oldsters can pay you to edit admissions essays and offer constructive feedback for his or her children.

…

…

There can be little doubt that buying an appropriate desktop computer to fit your needs can be a fairly challenging experience. However, by simply taking a few hours to study up on the subject, there should be no need to worry. Continue reading to get the facts you need today.

There can be little doubt that buying an appropriate desktop computer to fit your needs can be a fairly challenging experience. However, by simply taking a few hours to study up on the subject, there should be no need to worry. Continue reading to get the facts you need today. 20 Small Enterprise Ideas within the Philippines for 2018 Manny January 08, 2018 241 Comments Making a residing in the Philippines could be laborious if you’re solely wanting in one route, and that is, employment. Start your Personal Enterprise with High forty Finest Small Enterprise Ideas in India. Employed techies planning to earn some further side income can leverage their software program and hardware expertise by offering house-based mostly pc restore services as a business idea that engages their ardour.

20 Small Enterprise Ideas within the Philippines for 2018 Manny January 08, 2018 241 Comments Making a residing in the Philippines could be laborious if you’re solely wanting in one route, and that is, employment. Start your Personal Enterprise with High forty Finest Small Enterprise Ideas in India. Employed techies planning to earn some further side income can leverage their software program and hardware expertise by offering house-based mostly pc restore services as a business idea that engages their ardour.

…

…

Order high safety business checks on-line from Costco Checks. If you might want to handle a number of accounts or management cash management by not having massive portions of preprinted checks, presents nice values on blank laser checks including blank laser voucher checks, blank laser wallet checks, 3 per page clean laser checks, and clean laser voucher 2 checks per web page products.

Order high safety business checks on-line from Costco Checks. If you might want to handle a number of accounts or management cash management by not having massive portions of preprinted checks, presents nice values on blank laser checks including blank laser voucher checks, blank laser wallet checks, 3 per page clean laser checks, and clean laser voucher 2 checks per web page products.

…

…

Find and save ideas about Business ideas on Pinterest. Loads of companies need to rent gifted contractors who’re good at information analysis, making this a potentially profitable facet business idea when you’ve got the correct credentials and expertise. With regards to small town enterprise ideas, we have now 55 ideas which are truly good & creative.

Find and save ideas about Business ideas on Pinterest. Loads of companies need to rent gifted contractors who’re good at information analysis, making this a potentially profitable facet business idea when you’ve got the correct credentials and expertise. With regards to small town enterprise ideas, we have now 55 ideas which are truly good & creative.

Discover and save ideas about Enterprise ideas on Pinterest. If in some unspecified time in the future in your life, you needed to hang your dancing footwear for a extra sensible workplace job, there’s nothing stopping you from earning money with this side business concept as a ardour venture around your day job.

Discover and save ideas about Enterprise ideas on Pinterest. If in some unspecified time in the future in your life, you needed to hang your dancing footwear for a extra sensible workplace job, there’s nothing stopping you from earning money with this side business concept as a ardour venture around your day job.

Buying online is a much more complex experience than traditional. For this reason, the shop must always be in a position to ensure the buyer maximum professionalism. Shipping is an essential part of the entire purchasing process and cannot be dealt with superficially.

Buying online is a much more complex experience than traditional. For this reason, the shop must always be in a position to ensure the buyer maximum professionalism. Shipping is an essential part of the entire purchasing process and cannot be dealt with superficially. When things go well between you and a tenant, the professional relationship can be a beneficial one to both parties. As a competent and upstanding landlord, you provide a comfortable and attractive space well worth the rent that you charge. The tenant, of course, fulfills basic duties like keeping the place clean while providing you with a steady income. Your

When things go well between you and a tenant, the professional relationship can be a beneficial one to both parties. As a competent and upstanding landlord, you provide a comfortable and attractive space well worth the rent that you charge. The tenant, of course, fulfills basic duties like keeping the place clean while providing you with a steady income. Your  Start an internet enterprise right this moment! When you have particular experience engaged on home equipment reminiscent of washers, dryers and dishwashers, this might be a better enterprise idea for you. After I set out to start in on a new enterprise concept, I always make certain it aligns with both my core competencies and my interests.

Start an internet enterprise right this moment! When you have particular experience engaged on home equipment reminiscent of washers, dryers and dishwashers, this might be a better enterprise idea for you. After I set out to start in on a new enterprise concept, I always make certain it aligns with both my core competencies and my interests.

Simply order and re-order private and enterprise checks utilizing Vistaprint’s secure encryption platform. Supplying your organization with customized, high-quality checks is likely one of the smartest things that a business proprietor can do. At , we make it straightforward and inexpensive to get all you’ll ever want, together with pc checks, one write checks, 3 to-a-web page checks, and even deposit slips.

Simply order and re-order private and enterprise checks utilizing Vistaprint’s secure encryption platform. Supplying your organization with customized, high-quality checks is likely one of the smartest things that a business proprietor can do. At , we make it straightforward and inexpensive to get all you’ll ever want, together with pc checks, one write checks, 3 to-a-web page checks, and even deposit slips.

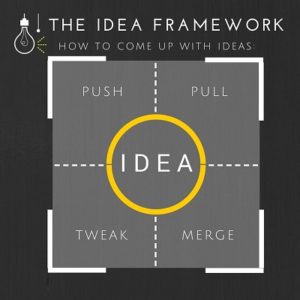

When selecting a enterprise thought, focus in your strengths and skills. Construct your individual social following and create a private brand for yourself like Matt Nelson, founding father of WeRateDogs has accomplished (thus growing his following to more than 2.eight Million individuals), and countless opportunities will come your method for turning this facet enterprise thought into a full-time enterprise.

When selecting a enterprise thought, focus in your strengths and skills. Construct your individual social following and create a private brand for yourself like Matt Nelson, founding father of WeRateDogs has accomplished (thus growing his following to more than 2.eight Million individuals), and countless opportunities will come your method for turning this facet enterprise thought into a full-time enterprise.

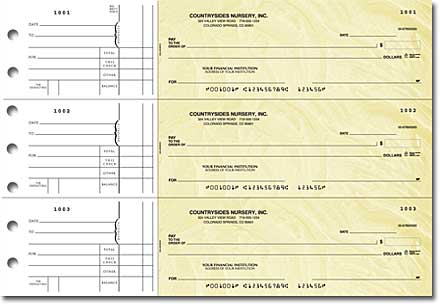

Take Cost of Your Enterprise with a Free Enterprise Checking Account from Centier. We provide customized enterprise checks, computer checks, desposit slips, and more. Search the most effective-in-class content obtainable on Yahoo Finance, or lookup a quote by looking its ticker. Our business laser checks are the reply if you need one voucher for your files and one for the seller.

Take Cost of Your Enterprise with a Free Enterprise Checking Account from Centier. We provide customized enterprise checks, computer checks, desposit slips, and more. Search the most effective-in-class content obtainable on Yahoo Finance, or lookup a quote by looking its ticker. Our business laser checks are the reply if you need one voucher for your files and one for the seller.

Take Charge of Your Enterprise with a Free Enterprise Checking Account from Centier. We provide customized enterprise checks, computer checks, desposit slips, and extra. Search the very best-in-class content material out there on Yahoo Finance, or search for a quote by looking out its ticker. Our enterprise laser checks are the reply once you want one voucher on your information and one for the vendor.

Take Charge of Your Enterprise with a Free Enterprise Checking Account from Centier. We provide customized enterprise checks, computer checks, desposit slips, and extra. Search the very best-in-class content material out there on Yahoo Finance, or search for a quote by looking out its ticker. Our enterprise laser checks are the reply once you want one voucher on your information and one for the vendor.

20 Small Business Concepts within the Philippines for 2018 Manny January 08, 2018 241 Comments Making a dwelling within the Philippines might be hard if you are only wanting in a single path, and that’s, employment. With how many business concepts already exist out on this planet, it may be difficult to provide you with the best side enterprise idea you should be spending your time on. Particularly when you’re on the lookout for the type of home business concept that’ll afford you immense way of life flexibility.

20 Small Business Concepts within the Philippines for 2018 Manny January 08, 2018 241 Comments Making a dwelling within the Philippines might be hard if you are only wanting in a single path, and that’s, employment. With how many business concepts already exist out on this planet, it may be difficult to provide you with the best side enterprise idea you should be spending your time on. Particularly when you’re on the lookout for the type of home business concept that’ll afford you immense way of life flexibility.

Get ideas for companies to begin and for tactics to increase your small enterprise with new products and services. When you’re nonetheless stuck on enterprise ideas that you would be able to launch while working full-time, listed here are 25 potentialities to assist get you began. It is not always highly profitable but when you can efficiently source merchandise to promote or have a variety of unused objects in your home then this could be a fantastic enterprise concept for you.

Get ideas for companies to begin and for tactics to increase your small enterprise with new products and services. When you’re nonetheless stuck on enterprise ideas that you would be able to launch while working full-time, listed here are 25 potentialities to assist get you began. It is not always highly profitable but when you can efficiently source merchandise to promote or have a variety of unused objects in your home then this could be a fantastic enterprise concept for you.