Six Sigma Excellence Precision in Manufacturing Processes

Six Sigma Excellence: Precision in Manufacturing Processes

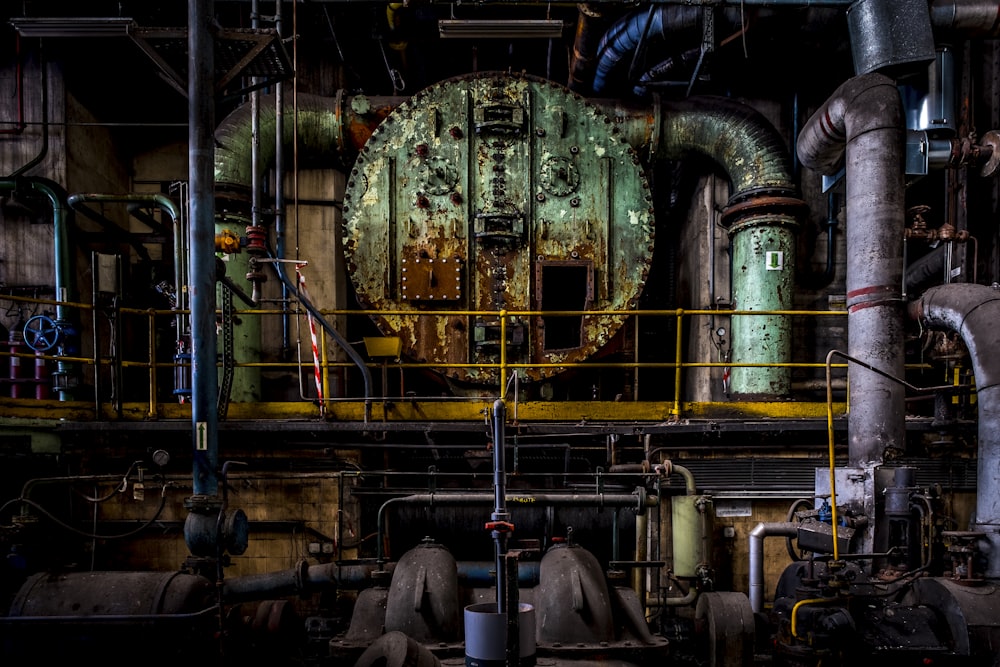

In the realm of manufacturing, achieving excellence in operational efficiency is the gold standard. One methodology that has stood the test of time in delivering this level of precision is Six Sigma. Let’s delve into the world of Six Sigma in manufacturing and explore how it transforms processes with unparalleled accuracy.

Understanding Six Sigma: A Methodical Approach

At its core, Six Sigma is a methodical approach to process improvement that seeks to eliminate defects and variations. Originating from Motorola in the 1980s, it has evolved into a globally recognized framework for quality management. The term “Six Sigma” itself refers to the goal of achieving processes that are 99.99966% defect-free.

Define Phase: Setting the Foundation

The Six Sigma journey begins with the Define phase, where the goals and parameters of a project are clearly outlined. This phase involves defining the problem, identifying customer requirements, and establishing a project scope. A well-defined foundation is crucial for the subsequent phases to deliver targeted improvements.

Measure Phase: Quantifying Performance Metrics

Once the parameters are set, the Measure phase comes into play. This involves collecting data to quantify the current state of the process. Performance metrics are established, and the team gains a deep understanding of the factors influencing the process. Data-driven decision-making becomes the cornerstone for the subsequent phases.

Analyze Phase: Uncovering Root Causes

In the Analyze phase, the focus shifts to uncovering the root causes of defects or variations. Statistical tools and techniques are applied to analyze data, identify patterns, and pinpoint the specific elements contributing to inefficiencies. This phase is pivotal in determining the strategic interventions needed for improvement.

Explore the transformative power of Six Sigma in manufacturing at Reltix.net. The platform offers insights into cutting-edge methodologies shaping operational excellence.

Improve Phase: Implementing Targeted Solutions

Armed with a thorough understanding of the process and its challenges, the Improve phase is about implementing targeted solutions. This involves generating and testing potential solutions to address the identified root causes. The goal is not just to make improvements but to make precise and impactful changes that align with organizational objectives.

Control Phase: Sustaining Operational Excellence

The journey doesn’t end with improvements; it extends to the Control phase. Here, mechanisms are established to monitor and sustain the gains achieved. Control charts, ongoing data collection, and continuous monitoring ensure that the process remains in a state of control, minimizing the risk of regression.

Lean Six Sigma: A Synergistic Approach

In many manufacturing environments, Six Sigma is often complemented by Lean principles, forming Lean Six Sigma. While Six Sigma focuses on minimizing variation and defects, Lean principles aim at eliminating waste and enhancing flow. Together, they create a synergistic approach to operational excellence, combining precision with efficiency.

Cultural Integration: Beyond Methodology

Six Sigma isn’t just a set of methodologies; it’s a cultural integration within organizations. The philosophy emphasizes a data-driven and customer-centric mindset at all levels. Employees are trained in Six Sigma principles, fostering a culture of continuous improvement and