Maximizing Production Efficiency for Optimal Manufacturing Output

Maximizing Production Efficiency for Optimal Manufacturing Output

In the fast-paced realm of manufacturing, the quest for enhanced production efficiency is an ever-evolving pursuit. This article delves into key strategies that businesses can employ to maximize their production efficiency and achieve optimal manufacturing output.

Streamlining Processes for Seamless Workflows

Efficiency begins with streamlined processes that ensure seamless workflows. By identifying and eliminating bottlenecks, redundancies, and unnecessary steps, manufacturers can optimize the flow of production. This not only reduces lead times but also enhances the overall speed and effectiveness of operations.

Investing in Advanced Technologies

Embracing cutting-edge technologies is paramount in the journey towards production efficiency. Automation, artificial intelligence, and data analytics play crucial roles in minimizing errors, improving precision, and enhancing overall productivity. Smart investments in these technologies can lead to significant gains in efficiency.

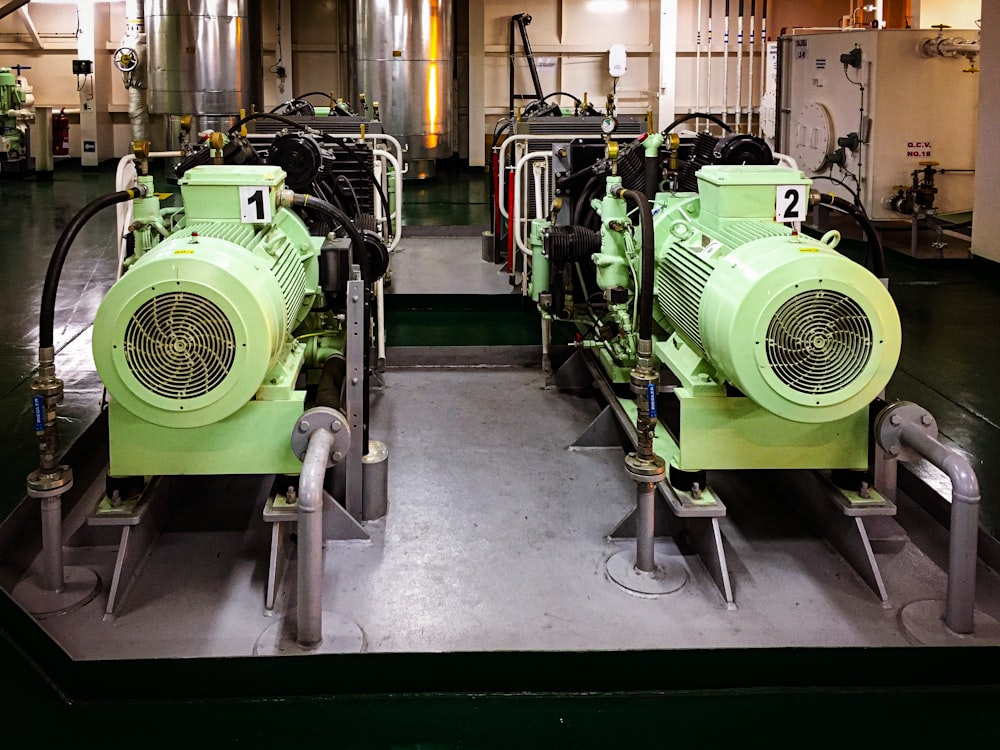

Optimizing Resource Utilization

Resource optimization is a cornerstone of efficient production. This involves not only utilizing materials judiciously but also making the most of manpower and machinery. By implementing lean manufacturing principles and just-in-time practices, businesses can minimize waste and ensure that resources are utilized to their fullest potential.

Employee Training and Skill Development

The human factor is integral to production efficiency. Investing in employee training and skill development not only enhances individual competencies but also contributes to a more capable and adaptable workforce. Well-trained employees are better equipped to handle complex tasks, troubleshoot issues, and contribute positively to the production process.

Implementing Lean Manufacturing Principles

Lean manufacturing is a systematic approach that aims to eliminate waste and optimize efficiency. From reducing excess inventory to improving equipment maintenance practices, the principles of lean manufacturing provide a framework for continuous improvement. Implementing these principles fosters a culture of efficiency throughout the organization.

Real-time Monitoring and Analysis

In the era of Industry 4.0, real-time monitoring and analysis are indispensable tools for production efficiency. Utilizing sensors and data analytics allows businesses to track key performance indicators, identify potential issues, and make data-driven decisions. This proactive approach minimizes downtime and enhances overall operational efficiency.

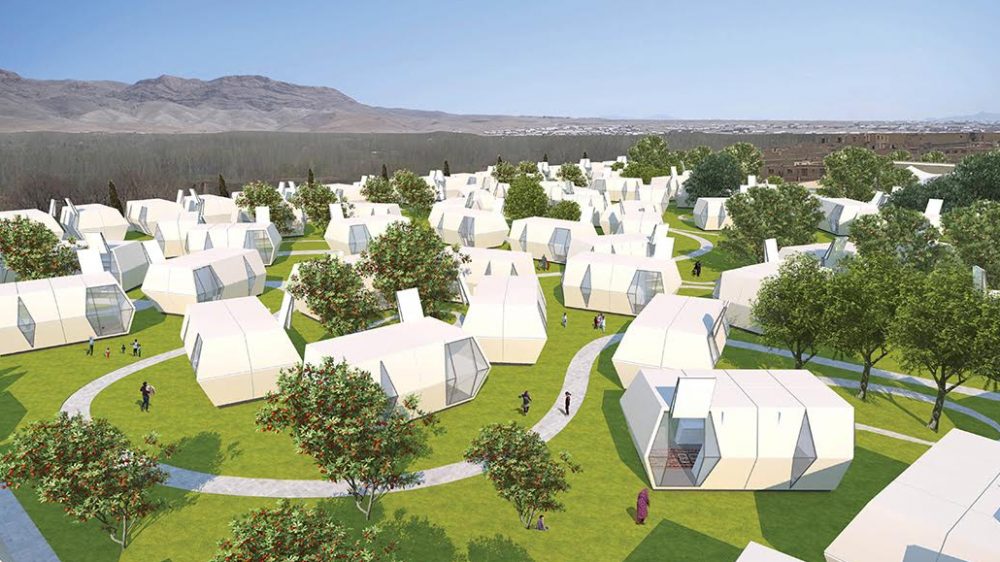

Adopting a Flexible Production Model

The ability to adapt to changing market demands is a hallmark of a truly efficient production system. Adopting a flexible production model allows businesses to respond swiftly to shifts in consumer preferences and market trends. This agility ensures that production remains aligned with current demands, minimizing the risk of overproduction or underproduction.

Creating a Culture of Continuous Improvement

Continuous improvement is not just a methodology; it’s a mindset. Fostering a culture of continuous improvement encourages employees at all levels to contribute ideas for enhancing efficiency. Regular reviews, feedback loops, and a commitment to evolving processes ensure that the pursuit of efficiency is an ongoing, collective effort.

Strategic Supply Chain Management

Efficient production is intricately linked to an optimized supply chain. Timely and reliable access to raw materials, components, and finished goods is vital for maintaining a smooth production flow. Strategic supply chain management involves building strong supplier relationships, mitigating risks, and implementing robust logistics solutions.

Embracing Sustainability for Long-term Efficiency

Efficiency