Insights Unleashed: The Power of Manufacturing Intelligence

In the ever-evolving landscape of manufacturing, the integration of intelligence is reshaping the industry. Manufacturing intelligence, a game-changer, goes beyond automation, offering a comprehensive approach to enhancing efficiency, precision, and overall productivity.

Data-Driven Decision Making

At the core of manufacturing intelligence lies the ability to harness and analyze vast amounts of data. This data-driven approach empowers decision-makers with real-time insights into production processes. From machine performance to supply chain dynamics, the ability to make informed decisions is a transformative force.

Optimizing Production Processes

Manufacturing intelligence optimizes production processes by identifying inefficiencies and bottlenecks. By analyzing data streams from various sources, including sensors and machinery, it becomes possible to fine-tune operations. This optimization not only increases throughput but also contributes to resource conservation and waste reduction.

Predictive Maintenance

One of the hallmarks of manufacturing intelligence is predictive maintenance. By leveraging data analytics and machine learning algorithms, manufacturers can predict when equipment is likely to fail. This proactive approach to maintenance minimizes downtime, extends the lifespan of machinery, and ultimately reduces operational costs.

Quality Control and Assurance

Ensuring product quality is a top priority in manufacturing. With the implementation of manufacturing intelligence, real-time monitoring and analysis of production parameters become feasible. Any deviations from quality standards trigger immediate alerts, allowing for corrective actions before defects can affect the final product.

Supply Chain Visibility

Manufacturing intelligence extends its reach beyond the factory floor to encompass the entire supply chain. By integrating data from suppliers, logistics, and distribution channels, manufacturers gain unparalleled visibility. This end-to-end transparency facilitates better demand forecasting, inventory management, and overall supply chain optimization.

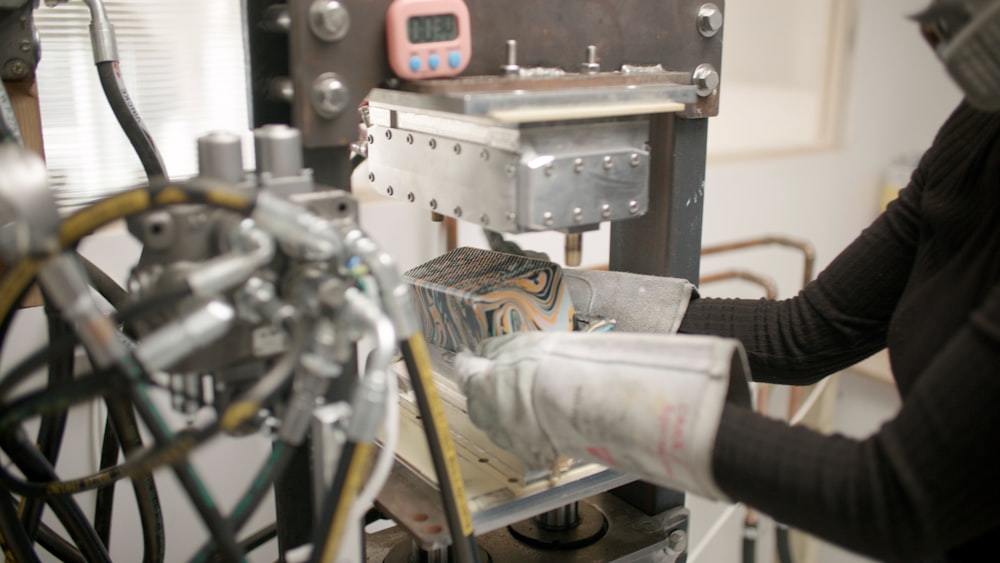

Human-Machine Collaboration

Contrary to fears of job displacement, manufacturing intelligence fosters human-machine collaboration. Intelligent systems complement the skills of human workers, handling repetitive tasks and providing valuable insights. This collaboration enhances overall productivity and creates a dynamic work environment where human creativity and machine efficiency converge.

Continuous Improvement Culture

Manufacturing intelligence instills a culture of continuous improvement. With real-time feedback on performance metrics, teams can iterate and refine processes continuously. This agile approach to improvement ensures that manufacturing operations stay adaptable and responsive to changing market demands.

Energy Efficiency and Sustainability

Efficiency in manufacturing extends to energy usage and sustainability. Manufacturing intelligence allows for the optimization of energy consumption by identifying areas where efficiency can be improved. This not only reduces the environmental impact but also contributes to cost savings in the long run.

Embracing Industry 4.0

Manufacturing intelligence is a key enabler of Industry 4.0, the fourth industrial revolution. The integration of intelligent systems, IoT devices, and data analytics defines this era. Embracing Industry 4.0 through manufacturing intelligence positions companies at the forefront of technological innovation.

Explore Manufacturing Intelligence at reltix.net

To delve deeper into the world of manufacturing intelligence and stay abreast of the latest advancements, visit reltix.net. This online platform serves as a hub for insights, discussions, and resources on how manufacturing intelligence is transforming the industry. Stay informed, stay ahead.