Revolutionizing Production The Era of Smart Factories

Revolutionizing Production: The Era of Smart Factories

In the realm of manufacturing, the rise of smart factories marks a transformative shift, where connectivity, automation, and data converge to redefine the production landscape.

Connectivity and Interoperability

Smart factories thrive on connectivity. Machines, devices, and systems communicate seamlessly, creating an interconnected ecosystem. This level of connectivity ensures real-time data sharing, facilitating synchronized operations across the entire manufacturing floor. The result is a more agile and responsive production environment.

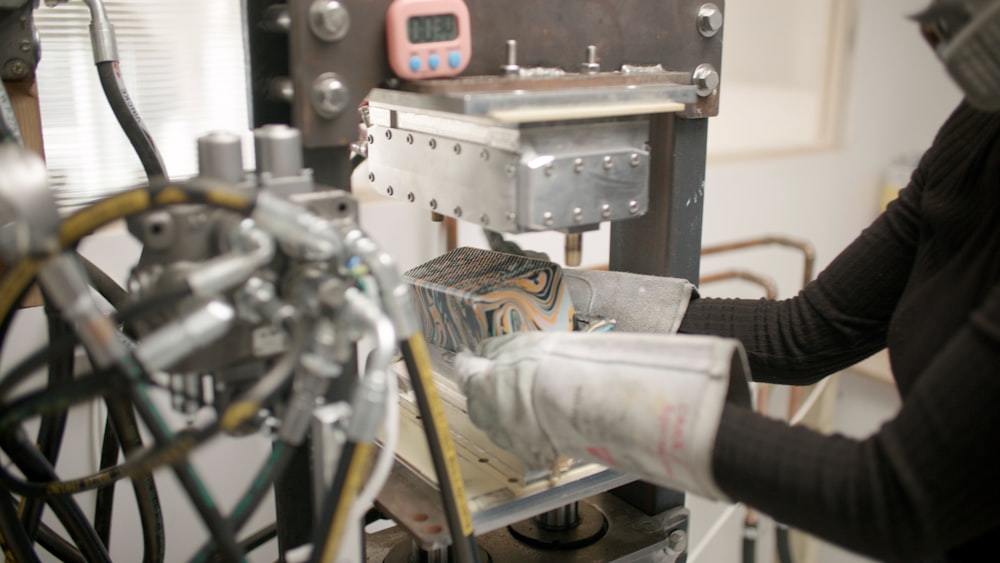

Automation and Robotics Integration

At the heart of smart factories is the integration of automation and robotics. Machines equipped with artificial intelligence (AI) perform tasks with precision and efficiency. From assembly lines to intricate processes, automation minimizes human intervention in routine operations, allowing skilled workers to focus on more complex and creative aspects of production.

IoT and Data Analytics

The Internet of Things (IoT) is a linchpin in the smart factory revolution. Sensors embedded in machines and equipment collect data, generating a wealth of information. This data, when analyzed through advanced analytics, provides valuable insights into production trends, equipment health, and overall operational efficiency. Smart factories leverage this intelligence for informed decision-making.

Predictive Maintenance for Efficiency

Smart factories excel in predictive maintenance. By monitoring equipment in real-time, these factories can predict when machinery is likely to fail. This proactive approach minimizes downtime, reduces the risk of costly breakdowns, and extends the lifespan of machinery. The result is a more efficient and reliable production process.

Digital Twin Technology

The concept of digital twins is a hallmark of smart factories. A digital twin is a virtual replica of a physical asset or process. In manufacturing, digital twins simulate and analyze real-world scenarios, enabling companies to optimize processes, troubleshoot potential issues, and test innovations in a risk-free virtual environment before implementation.

Supply Chain Visibility and Flexibility

Smart factories extend their influence beyond the production floor to encompass the entire supply chain. Enhanced visibility allows manufacturers to monitor inventory levels, track shipments, and respond dynamically to changes in demand. This flexibility ensures a streamlined supply chain that adapts to market fluctuations with ease.

Cybersecurity in the Digital Age

As factories become more connected, the importance of cybersecurity intensifies. Smart factories invest in robust cybersecurity measures to protect sensitive data, intellectual property, and ensure the integrity of operations. Proactive cybersecurity measures are integral to safeguarding the interconnected web of smart manufacturing systems.

Human-Machine Collaboration and Upskilling

Contrary to concerns about job displacement, smart factories emphasize human-machine collaboration. Skilled workers partner with intelligent machines, combining the strengths of both. Upskilling programs ensure that the workforce remains adept at working alongside advanced technologies, fostering a harmonious coexistence between humans and machines.

Sustainability and Energy Efficiency

Smart factories prioritize sustainability. Through data-driven insights, manufacturers can identify areas for energy optimization, waste reduction, and overall environmental impact mitigation. The result is a more sustainable and eco-friendly approach to manufacturing that aligns with global efforts towards a greener future.

Explore the Future of Manufacturing at reltix.net

To delve deeper into the world of smart