Strategic Lifecycle Assessment for Industrial Equipment

Strategic Lifecycle Assessment for Industrial Equipment

Understanding the lifecycle of industrial equipment is more than a technicality; it’s a strategic imperative for sustainable and efficient operations. Let’s delve into the significance of Industrial Equipment Lifecycle Assessment and its transformative impact on industrial landscapes.

Pioneering Sustainability through Assessment

The journey of industrial equipment begins long before its installation on the factory floor and extends far beyond its operational life. Industrial Equipment Lifecycle Assessment pioneers sustainability by analyzing the entire lifespan of equipment. This comprehensive approach involves evaluating the environmental impact of manufacturing, transportation, installation, operation, and eventual disposal or recycling. The goal is to minimize the ecological footprint of industrial operations.

Informed Decision-Making from Cradle to Grave

Lifecycle assessment empowers industries with a wealth of information from the cradle to the grave of industrial equipment. By understanding the environmental and economic implications at each stage, decision-makers can make informed choices. Whether it’s selecting materials with lower environmental impact during manufacturing or optimizing end-of-life disposal processes, the insights gained from lifecycle assessment contribute to strategic decision-making.

Maximizing Efficiency through Design Optimization

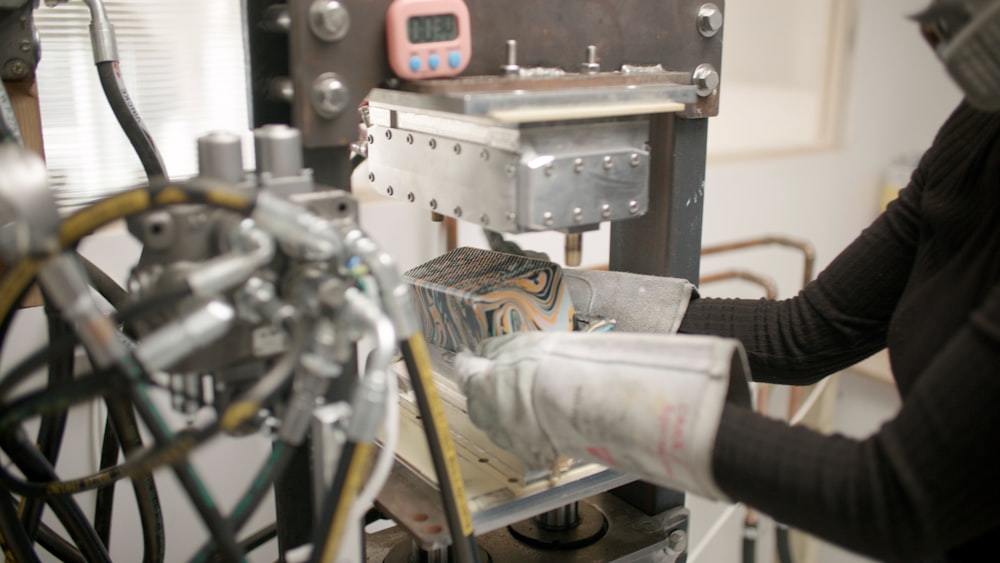

Efficiency is the linchpin of industrial success, and it begins with design. Industrial Equipment Lifecycle Assessment focuses on design optimization to maximize efficiency throughout the equipment’s life. This includes selecting materials that enhance durability, ease of maintenance, and recyclability. The result is equipment that not only performs optimally but also aligns with long-term efficiency goals.

Adaptive Maintenance Strategies

Maintenance is an integral part of the industrial equipment lifecycle, and lifecycle assessment guides the development of adaptive maintenance strategies. By analyzing the wear and tear patterns, anticipating potential failures, and factoring in the environmental impact of maintenance activities, industries can implement strategies that not only extend equipment lifespan but also contribute to overall sustainability.

Energy-Efficient Operation

The operational phase of industrial equipment is a significant contributor to energy consumption. Lifecycle assessment identifies opportunities for energy-efficient operation. Whether it involves optimizing processes, upgrading to energy-efficient technologies, or implementing smart operational practices, the focus is on reducing energy consumption throughout the equipment’s operational life.

Circular Economy Integration

Embracing a circular economy is a hallmark of sustainability, and Industrial Equipment Lifecycle Assessment is a key player in this integration. By designing equipment with recyclability in mind and implementing effective end-of-life recycling or repurposing strategies, industries contribute to the circular economy. This approach minimizes waste, conserves resources, and supports a more sustainable industrial ecosystem.

Regulatory Compliance and Risk Mitigation

The regulatory landscape is ever-evolving, and compliance is non-negotiable. Lifecycle assessment ensures that industrial equipment meets or exceeds environmental regulations at every stage. This proactive approach not only mitigates the risk of non-compliance but also positions industries as responsible stewards of the environment, enhancing their reputation and reducing regulatory risks.

Cost Savings through Lifecycle Planning

Strategic planning is at the heart of Industrial Equipment Lifecycle Assessment, and this planning extends to cost management. By anticipating and planning for future costs, industries can achieve significant cost savings. This includes factoring in maintenance costs, energy expenses, and potential regulatory