Optimizing Efficiency Industrial Process Optimization Services

Optimizing Efficiency: Industrial Process Optimization Services

In the dynamic realm of industry, the pursuit of efficiency is a constant endeavor. Industrial Process Optimization Services emerge as the architects of operational excellence, navigating the intricate landscape of processes to unlock new levels of efficiency and productivity. Let’s delve into the world of optimization and explore how these services redefine the efficiency game.

Precision Engineering: Crafting Efficiency Blueprints

At the core of Industrial Process Optimization Services is the art of precision engineering. These services involve meticulously crafting efficiency blueprints tailored to the specific needs of industrial processes. Precision engineering identifies bottlenecks, streamlines workflows, and designs optimization strategies that serve as the foundation for enhanced efficiency.

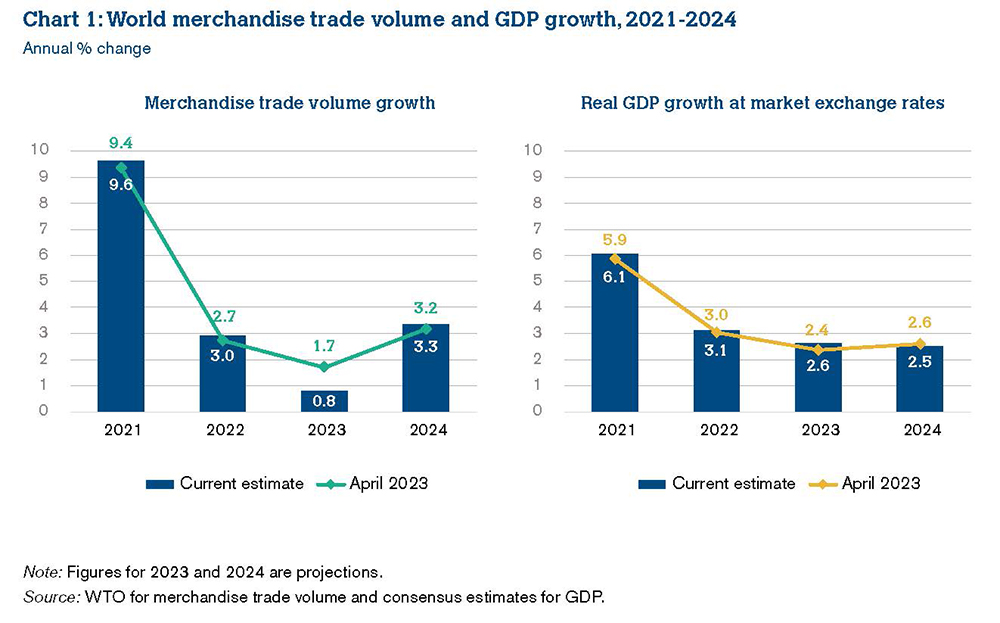

Data-Driven Decision-Making: The Navigator

In the journey toward efficiency, data becomes the guiding navigator. Industrial Process Optimization Services leverage data-driven decision-making as a fundamental principle. By analyzing real-time and historical data, decision-makers gain insights into process performance, enabling strategic decisions that lead to continuous improvement and heightened efficiency.

Lean Principles: Trimming Excesses

Industrial efficiency embraces the lean principles that focus on trimming excesses and maximizing value. Industrial Process Optimization Services integrate lean methodologies to eliminate waste, reduce downtime, and optimize resource utilization. This trimming of excesses ensures that every aspect of the industrial process contributes directly to efficiency gains.

Automation Symphony: Orchestrating Efficiency

Automation takes center stage in the symphony of Industrial Process Optimization Services. Whether through robotic process automation, AI-driven decision support, or smart machinery, automation orchestrates a seamless performance. This symphony of automation optimizes repetitive tasks, minimizes errors, and enhances overall process efficiency.

Continuous Monitoring: Vigilant Oversight

Efficiency is not a one-time achievement; it requires vigilant oversight. Industrial Process Optimization Services incorporate continuous monitoring mechanisms. These systems provide real-time visibility into process metrics, enabling quick identification of deviations and the proactive resolution of issues that could impact efficiency.

Scalability Solutions: Adapting to Growth

In the ever-evolving landscape of industry, scalability is a vital consideration. Industrial Process Optimization Services provide scalability solutions, ensuring that optimization strategies can adapt to changes in production volume, market demands, and business expansion. This adaptability ensures sustained efficiency in the face of growth.

Employee Empowerment: Efficiency Partners

Efficiency is not solely a technological endeavor; it involves the active participation of the workforce. Industrial Process Optimization Services prioritize employee empowerment. Through training programs and involvement in the optimization process, employees become efficiency partners, contributing their expertise to the continuous improvement journey.

Sustainability Integration: Efficient and Green

Efficiency and sustainability go hand in hand in modern industry. Industrial Process Optimization Services integrate sustainability practices into efficiency initiatives. This involves optimizing energy consumption, reducing waste, and adopting eco-friendly technologies, creating a synergy between operational efficiency and environmental responsibility.

Comprehensive Training: Nurturing Expertise

Efficiency gains are amplified when the workforce is equipped with the right skills. Industrial Process Optimization Services include comprehensive training programs. These programs nurture expertise among operators and maintenance personnel, ensuring that they are proficient in handling optimized processes and contributing to ongoing efficiency initiatives.

Industrial Process Optimization Services Solutions

For industries