Elevate Efficiency Industrial Equipment Upgrade Solutions

Elevate Efficiency: Industrial Equipment Upgrade Solutions

In the ever-evolving landscape of industry, the pursuit of efficiency is a relentless endeavor. Discover the transformative potential of Industrial Equipment Upgrade Solutions and how they propel industrial operations into a realm of heightened performance and competitiveness.

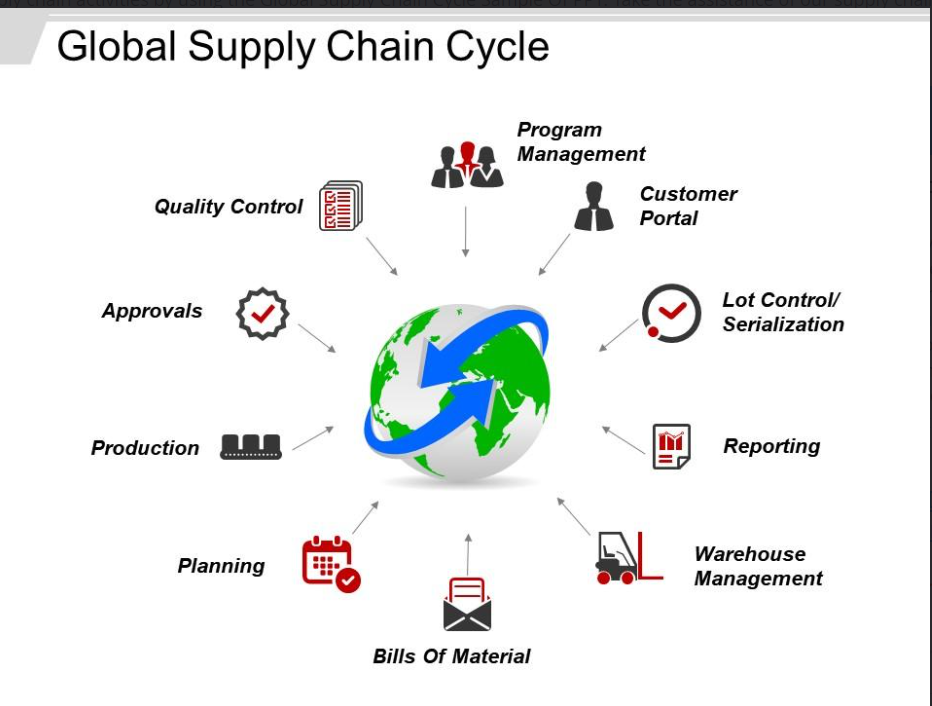

Tailored Solutions for Diverse Needs

One size doesn’t fit all in the industrial world, and Industrial Equipment Upgrade Solutions recognize this. These solutions are not generic fixes; they are tailored to meet the specific needs of diverse industries and operational contexts. Whether it’s enhancing the capabilities of machinery, improving automation, or integrating cutting-edge technologies, tailored solutions ensure that the upgrade aligns seamlessly with the unique requirements of each industrial setting.

Technological Advancements for Modernization

Industrial Equipment Upgrade Solutions serve as a gateway to modernization. In a world where technology advances at a rapid pace, keeping industrial equipment up-to-date is paramount. Upgrading machinery involves incorporating the latest technological advancements, from smart sensors and IoT connectivity to advanced automation. This infusion of modern technology not only optimizes performance but also positions industries at the forefront of the Fourth Industrial Revolution.

Cost-Effective Alternatives to Replacement

Replacing outdated equipment can be a significant financial burden. Industrial Equipment Upgrade Solutions offer a cost-effective alternative. Rather than investing in entirely new machinery, industries can strategically upgrade existing equipment. This approach not only saves costs but also extends the lifespan of valuable assets. It’s a pragmatic solution that aligns with the principles of efficiency and resource optimization.

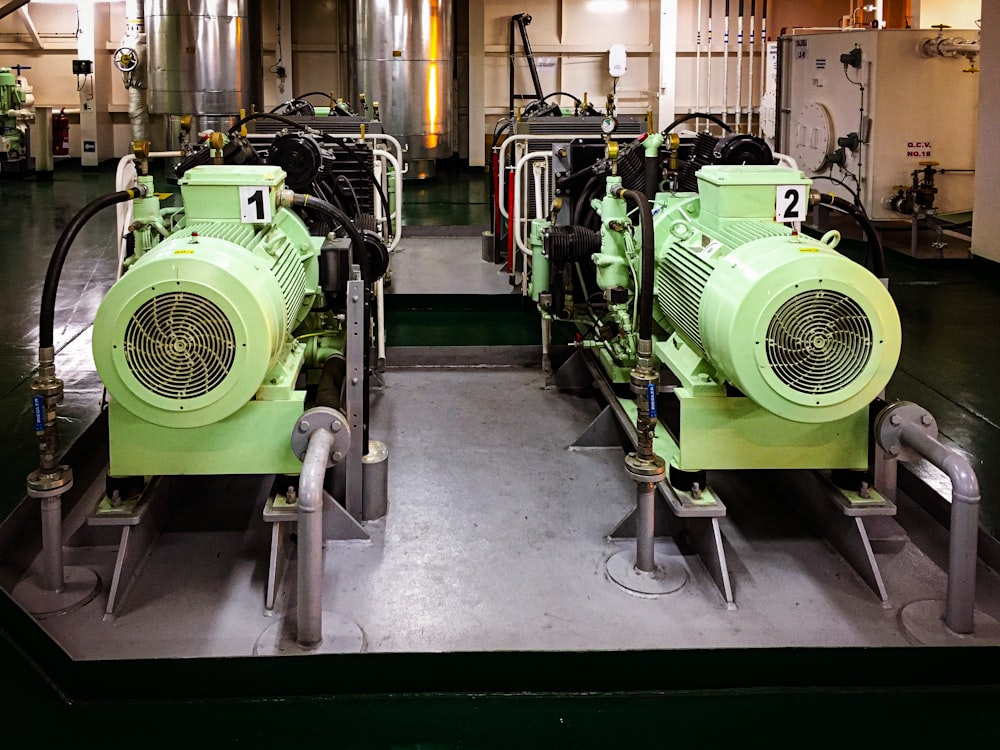

Enhancing Productivity through Automation

Automation is a key driver of productivity in the industrial landscape, and Industrial Equipment Upgrade Solutions are a catalyst for its integration. Upgrading machinery to include advanced automation features streamlines processes, reduces manual intervention, and enhances overall productivity. Whether it’s automating repetitive tasks or implementing robotics for precision operations, the result is a more efficient and productive industrial environment.

Adaptive Maintenance Strategies for Reliability

Reliability is the cornerstone of industrial success, and Industrial Equipment Upgrade Solutions contribute to it through adaptive maintenance strategies. Upgraded machinery often includes predictive maintenance capabilities, allowing industries to anticipate and address potential issues before they impact operations. This proactive approach minimizes downtime, enhances equipment reliability, and fosters a culture of continuous and adaptive maintenance.

Sustainability Practices for Responsible Operations

Sustainability is not just a buzzword; it’s a commitment to responsible operations. Industrial Equipment Upgrade Solutions incorporate sustainability practices by improving energy efficiency, reducing emissions, and optimizing resource utilization. Upgrading machinery with a focus on sustainability aligns with environmental regulations, meets corporate responsibility goals, and contributes to a greener and more sustainable industrial footprint.

Customization for Varied Industrial Processes

Industries are diverse, and so are their processes. Industrial Equipment Upgrade Solutions recognize the need for customization. Whether it’s adapting equipment for specific production lines, incorporating industry-specific features, or tailoring automation to match unique processes, customization ensures that upgrades enhance the efficiency of operations without compromising the integrity of individual industrial processes.

Seamless Integration with Existing Systems

The fear of disrupting existing operations often hinders the adoption of new solutions.