Optimizing Efficiency Industrial Facility Layout Strategies

Optimizing Efficiency: Industrial Facility Layout Strategies

In the realm of manufacturing, the layout of an industrial facility plays a pivotal role in determining overall efficiency. A well-designed layout not only enhances productivity but also contributes to cost savings and a streamlined workflow. Let’s delve into some key strategies for optimizing industrial facility layouts.

1. Understanding Workflow Dynamics

A fundamental step in designing an efficient industrial facility layout is understanding the workflow dynamics. By mapping out the various processes involved in production, it becomes possible to identify bottlenecks and areas for improvement. This initial understanding sets the stage for a layout that aligns seamlessly with the production flow.

2. Embracing Lean Manufacturing Principles

Implementing lean manufacturing principles is a cornerstone of efficient industrial facility layout. This involves minimizing waste, optimizing resource utilization, and creating a workspace where every element serves a purpose. Lean layouts often incorporate practices such as 5S (Sort, Set in order, Shine, Standardize, Sustain) to maintain order and cleanliness.

3. Just-in-Time (JIT) Integration

The adoption of Just-in-Time (JIT) manufacturing principles is another strategy to enhance efficiency. JIT focuses on producing goods just in time to meet customer demand, thereby reducing excess inventory and associated carrying costs. Integrating JIT principles into the facility layout ensures a smoother production process with minimal storage requirements.

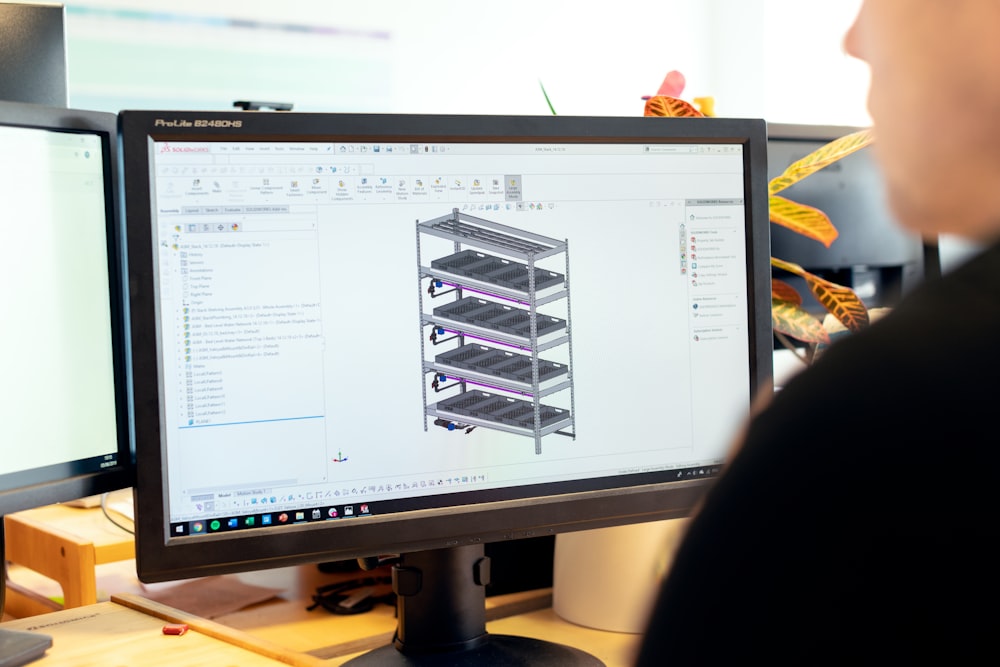

4. Intelligent Inventory Control

Efficient industrial facility layouts incorporate intelligent inventory control measures. This involves strategically placing inventory within the facility to minimize travel distances and streamline the picking process. Utilizing technology such as RFID (Radio-Frequency Identification) can further enhance accuracy in tracking and managing inventory.

5. Technology Integration for Production Planning

In the modern manufacturing landscape, technology plays a crucial role in optimizing production planning. Industrial facility layouts benefit from the integration of advanced software systems that enable real-time monitoring, predictive maintenance, and data-driven decision-making. Embracing Industry 4.0 technologies ensures a facility that is not only efficient but also adaptive to changing demands.

6. Material Handling Efficiency

Efficient material handling is a key determinant of overall operational efficiency. Well-designed pathways, automated conveyance systems, and strategically located storage areas contribute to minimizing material handling times. The goal is to reduce the time it takes for raw materials to move through the production process, ultimately accelerating the overall manufacturing cycle.

7. Flexibility and Scalability

A well-designed industrial facility layout should possess inherent flexibility and scalability. The ability to adapt to changes in production volume or product mix ensures that the facility remains responsive to dynamic market demands. Scalability, in particular, allows for the seamless expansion of production capabilities without major disruptions.

8. Integration of Sustainable Practices

Sustainability is an increasingly important consideration in industrial facility layout design. Incorporating eco-friendly practices not only aligns with corporate social responsibility but can also result in cost savings. Green layouts may include energy-efficient lighting, waste reduction strategies, and the integration of renewable energy sources.

In the quest for an optimized industrial facility layout, each of these strategies plays a crucial role. By understanding workflow dynamics, embracing lean principles, integrating technology, and