Revitalizing Efficiency Industrial Equipment Modernization Strategies

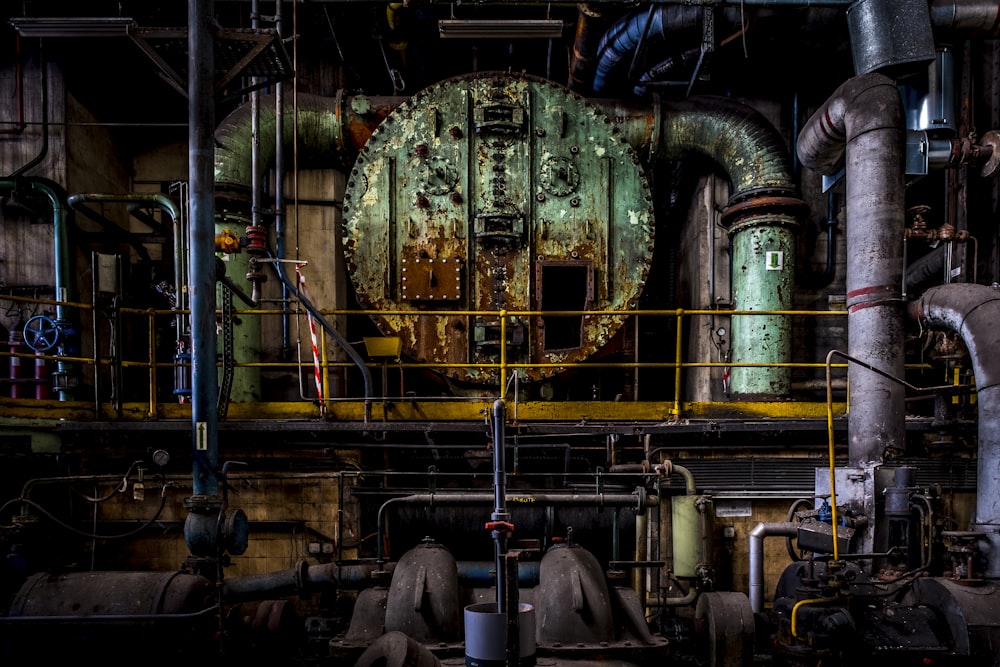

Revitalizing Efficiency: Industrial Equipment Modernization Strategies

In the dynamic landscape of industry, staying ahead means more than just keeping up; it means embracing change and revitalizing efficiency. Explore the realm of Industrial Equipment Modernization Strategies and how they serve as the catalysts for elevating operational performance and securing a competitive edge.

Customized Solutions for Tailored Transformation

The journey towards efficiency begins with customization. Industrial Equipment Modernization Strategies are not one-size-fits-all; they are bespoke solutions crafted to meet the specific needs of each industry. Whether it’s upgrading machinery, integrating advanced technologies, or optimizing operational processes, customization ensures a tailored transformation that aligns seamlessly with the unique requirements of industrial settings.

Technological Integration: A Leap into Modernity

Modernization is synonymous with technological integration, and Industrial Equipment Modernization Strategies are the stepping stones into modernity. Upgrading machinery with the latest technologies, from IoT sensors to advanced automation, propels industries into the Fourth Industrial Revolution. This integration is not just about keeping up with trends; it’s about leveraging technology to unlock new levels of efficiency and competitiveness.

Adaptive Automation for Operational Agility

Adaptability is a key attribute in modern industrial operations, and Industrial Equipment Modernization Strategies embrace adaptive automation. These strategies involve implementing automation systems that can adapt to changes in demand, production requirements, or external factors. It’s about cultivating operational agility, ensuring that industrial processes can seamlessly adjust to evolving circumstances for optimal efficiency.

Data-Driven Decision-Making: Insights for Excellence

In the age of big data, Industrial Equipment Modernization Strategies leverage data-driven decision-making. Upgraded systems provide real-time insights into operational performance, production metrics, and resource utilization. Armed with this data, decision-makers can make informed choices, identify areas for improvement, and strategically steer operations towards excellence.

Sustainability Integration: Beyond Efficiency

Efficiency and sustainability go hand in hand in modern industrial practices. Industrial Equipment Modernization Strategies extend beyond mere efficiency gains; they integrate sustainability practices into the fabric of operations. Whether it’s optimizing energy consumption, reducing waste, or adopting eco-friendly technologies, modernization becomes a pathway to responsible and sustainable industrial practices.

Modular Upgrades for Scalable Growth

Scalability is a cornerstone of industrial success, and Industrial Equipment Modernization Strategies prioritize modular upgrades. These upgrades allow industries to scale their operations efficiently, whether it’s expanding production capacity, integrating new technologies, or diversifying product lines. The modular approach ensures that modernization efforts align with the pace and scale of industrial growth.

Predictive Maintenance: Proactive Reliability

Reliability is non-negotiable in industrial settings, and Industrial Equipment Modernization Strategies introduce predictive maintenance as a proactive reliability solution. Upgraded systems incorporate predictive analytics to monitor the health of equipment, predict potential failures, and schedule maintenance activities strategically. This foresighted approach minimizes downtime, enhances equipment reliability, and fosters a culture of proactive maintenance.

Employee Training: Empowering the Workforce

Modernization isn’t just about machines; it’s about empowering the workforce. Industrial Equipment Modernization Strategies include comprehensive employee training programs. These programs ensure that the workforce is equipped with the skills and knowledge needed to operate, maintain, and optimize upgraded systems. An empowered workforce becomes an invaluable