Innovative Precision Industrial 3D Printing Solutions

Innovative Precision: Industrial 3D Printing Solutions

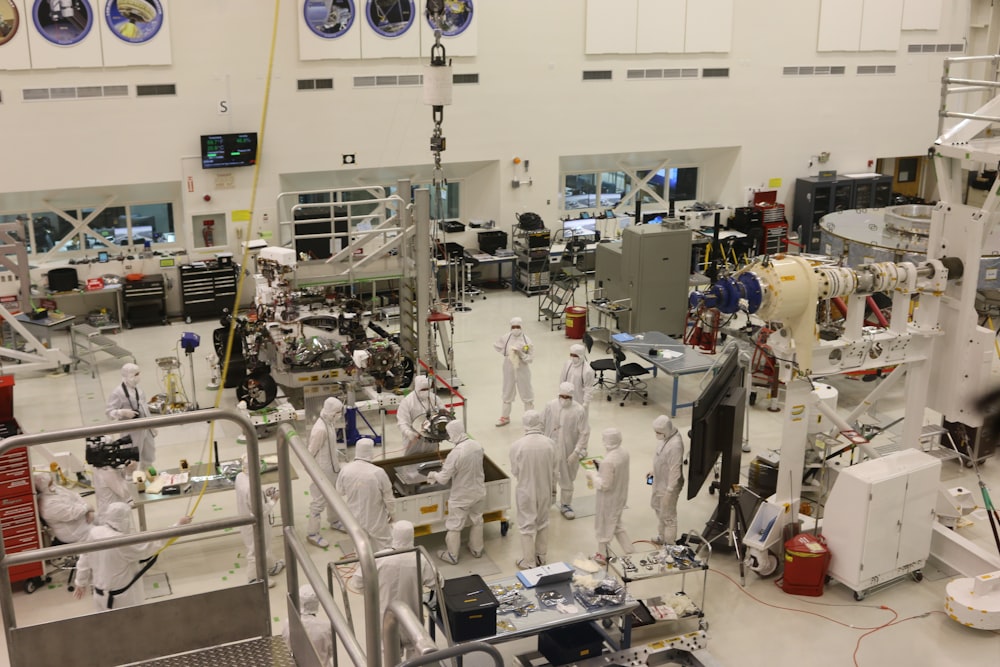

Embracing the future of manufacturing, Industrial 3D printing services have emerged as a game-changer, offering unparalleled precision and efficiency. In the realm of additive manufacturing, the possibilities are vast, reshaping how industries conceptualize, prototype, and produce.

Revolutionizing Prototyping with Precision

One of the key realms where Industrial 3D printing services shine is in prototyping. Traditional prototyping methods often involve time-consuming processes and significant costs. However, with 3D printing, intricate prototypes can be produced swiftly and with unparalleled precision. This not only accelerates product development but also allows for rapid iteration and refinement.

Complex Geometries: Unleashing Design Freedom

Industrial 3D printing services empower designers with newfound freedom. Complex geometries that were once challenging or impossible to produce using traditional methods become feasible with 3D printing. This flexibility in design opens up avenues for innovation, enabling the creation of components and products with enhanced functionality and performance.

Materials Innovation: Beyond Traditional Boundaries

The materials used in 3D printing have expanded beyond traditional boundaries. From plastics and metals to ceramics and composites, Industrial 3D printing services offer a diverse range of materials to suit specific application requirements. This versatility is invaluable, allowing manufacturers to choose materials tailored to the performance and durability needed for their products.

Customization at Scale: Tailoring Solutions

One of the standout features of Industrial 3D printing is its ability to customize at scale. Mass production doesn’t mean sacrificing individualization. Whether it’s producing personalized medical implants or creating unique components for aerospace applications, Industrial 3D printing services allow for cost-effective customization without compromising efficiency.

Reltix.net: Your Hub for Industrial 3D Printing Insights

For a deeper dive into the world of Industrial 3D printing services, explore Industrial 3D Printing Services at Reltix.net. This platform provides insights, case studies, and the latest developments in the realm of additive manufacturing. Stay informed to harness the full potential of 3D printing for your industrial needs.

Time and Cost Efficiency: Streamlining Production

Efficiency is at the core of Industrial 3D printing services. Traditional manufacturing processes often involve multiple steps, tooling, and complex setups. 3D printing simplifies the production process, reducing lead times and minimizing costs. This time and cost efficiency make it an attractive option for various industries seeking agile and economical manufacturing solutions.

Sustainability in Manufacturing: Reducing Waste

In an era where sustainability is a top priority, Industrial 3D printing services align with eco-friendly practices. The additive nature of 3D printing reduces material waste compared to subtractive manufacturing methods. This sustainability aspect is not only environmentally conscious but also contributes to cost savings by using materials more efficiently.

On-Demand Production: Meeting Market Demands

The concept of on-demand production is revolutionizing how industries manage inventory and respond to market demands. Industrial 3D printing services enable businesses to produce components or products as needed, eliminating the need for large stockpiles. This flexibility in production aligns with the dynamic nature of today’s markets.

Challenges and Future Innovations: Staying Ahead

While Industrial 3D printing services have made remarkable strides, challenges remain, including