Navigating Home Renovation Costs: A Practical Estimation Guide

Introduction: Decoding the Complexity of Home Renovation Cost Estimation

Embarking on a home renovation project is an exciting endeavor, but understanding and estimating the associated costs is a crucial first step. In this article, we’ll delve into the intricacies of home renovation cost estimation, providing a practical guide for homeowners looking to embark on a successful remodeling journey.

Assessing Project Scope: Defining the Renovation Goals

The first step in accurate cost estimation is a clear understanding of the renovation goals. Assess the project scope by identifying specific areas or rooms that require renovation. Determine whether it’s a cosmetic upgrade, structural modification, or a complete overhaul. A detailed project scope forms the foundation for accurate cost calculations.

Researching Material Costs: Navigating the Price Landscape

Material costs constitute a significant portion of any renovation budget. Conduct thorough research on the prices of materials such as flooring, fixtures, paint, and appliances. Compare prices from different suppliers, considering factors like quality, durability, and style. This diligence ensures an informed decision-making process when estimating material expenses.

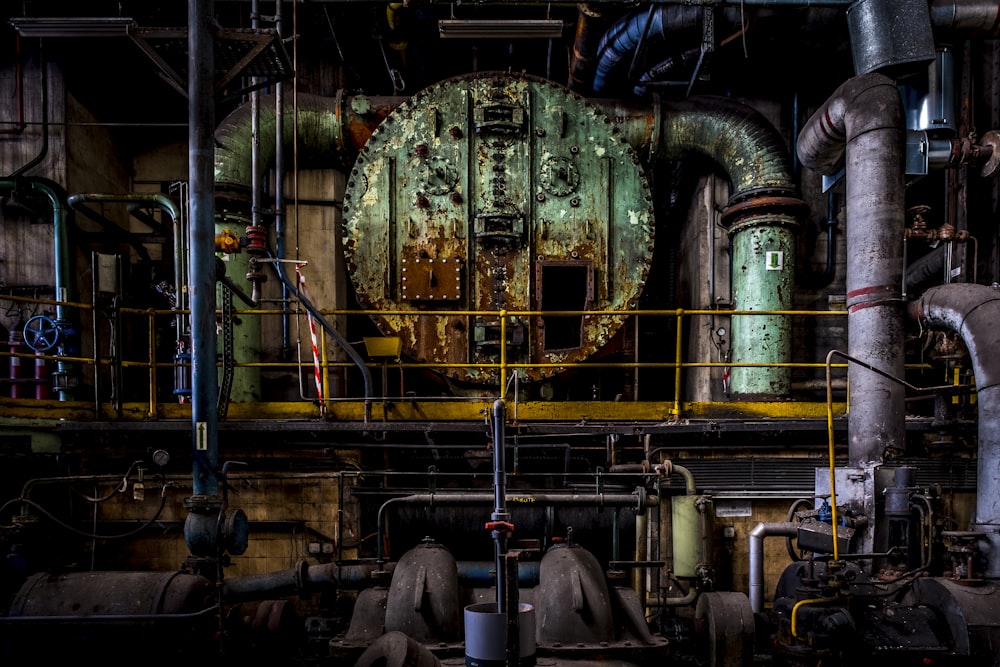

Labor Costs and Professional Services: Factoring in Expertise

Estimating labor costs is essential for an accurate budget. Research local labor rates for skilled trades, contractors, and other professionals involved in the project. Obtain multiple quotes and consider the expertise and reputation of the professionals. Factoring in skilled labor costs ensures that the renovation is executed with precision and meets industry standards.

Contingency Fund: Allowing Room for the Unexpected

No matter how well-planned a renovation is, unexpected surprises can arise. Incorporate a contingency fund into the budget to account for unforeseen issues or additional expenses that may surface during the project. A contingency fund provides a financial safety net and prevents budget overruns, ensuring the renovation stays on track.

Permit and Inspection Costs: Complying with Regulations

Many renovation projects require permits and inspections to comply with local building codes and regulations. Research the costs associated with obtaining necessary permits and scheduling inspections. Failure to account for these costs can lead to delays and legal complications. Including permit and inspection fees in the budget ensures a smooth and compliant renovation process.

Project Timeline: Considering Time-Related Expenses

Time is money in the realm of home renovation. Consider the duration of the project and its impact on costs. Extended timelines may incur additional expenses for renting temporary accommodation, storage, or dealing with increased labor costs. Efficient project management and a realistic timeline contribute to cost-effectiveness in the long run.

DIY vs. Professional Services: Weighing the Cost-Benefit Ratio

Homeowners often face the decision of whether to tackle certain aspects of the renovation themselves or hire professionals. While DIY can save money, it’s crucial to assess the cost-benefit ratio. Consider the complexity of tasks, required skills, and potential risks. Finding the right balance between DIY and professional services is key to optimizing the budget.

Comparing Quotes: Gathering Multiple Estimates

Gathering multiple quotes from contractors and service providers is a prudent practice. This not only helps in understanding the market rate for services but also provides