Faster Shipping Reshaping Ecommerce Logistics

The Rise of Instant Gratification in E-commerce

Consumers today expect things faster than ever before. The convenience of online shopping is amplified by the speed of delivery. Gone are the days when a week or more was considered acceptable waiting time for an online purchase. Now, same-day or next-day delivery is becoming the norm, and even faster options, like one-hour delivery windows, are popping up in major metropolitan areas. This shift in consumer expectations is fundamentally reshaping the entire landscape of e-commerce logistics.

Pressure on Logistics Providers to Adapt

This demand for speed puts immense pressure on logistics providers. They’re forced to innovate and invest heavily in infrastructure, technology, and workforce optimization to meet these increasingly stringent delivery deadlines. This includes everything from optimizing warehouse operations and employing advanced routing algorithms to investing in last-mile delivery solutions like drone technology and automated delivery vehicles.

The Expanding Role of Technology in Speeding Up Delivery

Technology is playing a crucial role in facilitating faster shipping. Real-time tracking systems keep customers informed about the location of their packages, managing expectations and reducing anxiety. Predictive analytics help businesses anticipate demand surges and optimize inventory levels, ensuring products are readily available for quick dispatch. Furthermore, sophisticated warehouse management systems automate picking, packing, and shipping processes, increasing efficiency and speed.

The Importance of Strategic Warehouse Placement

The location of warehouses is no longer a secondary consideration; it’s a critical factor in achieving faster shipping times. Strategically placing distribution centers closer to major population centers significantly reduces transit times. This often involves a shift towards a more decentralized warehousing model, with multiple smaller facilities strategically dispersed rather than relying on a few large, centralized hubs. This approach, while more costly in terms of infrastructure, dramatically improves delivery speeds.

The Impact on Last-Mile Delivery Strategies

The final leg of the delivery journey, the last mile, presents a unique set of challenges. Traditional delivery methods can be slow and inefficient, particularly in congested urban areas. Consequently, companies are exploring innovative solutions like crowdsourced delivery networks, utilizing independent contractors for quicker delivery, and exploring the potential of autonomous vehicles and drone technology to bypass traffic congestion and reach customers faster.

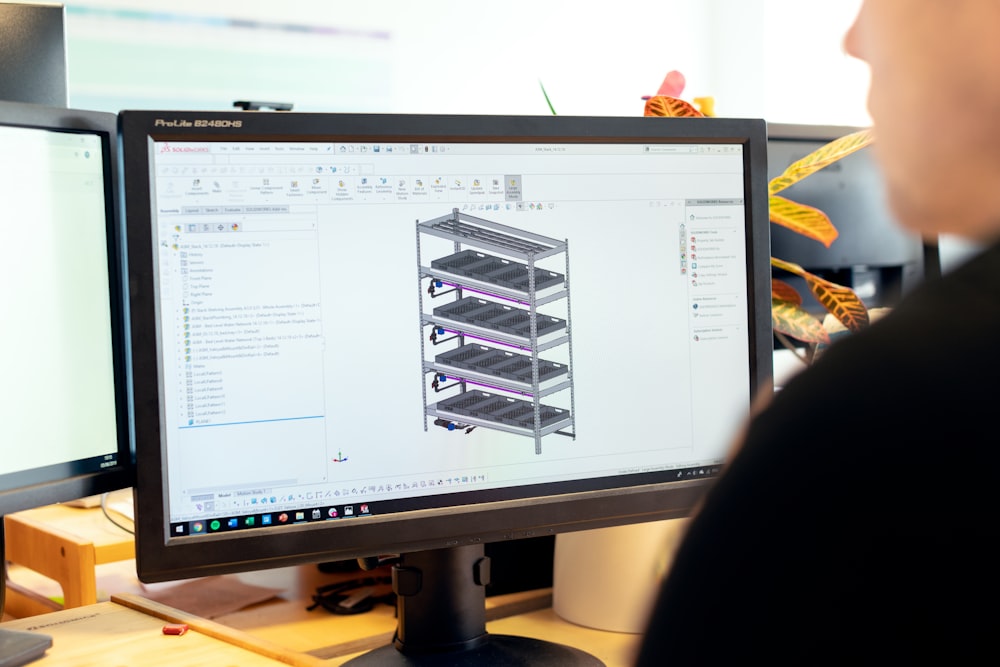

The Growing Importance of Micro-Fulfillment Centers

Micro-fulfillment centers, smaller automated warehouses located closer to consumers, are gaining traction. They address the challenge of last-mile delivery by reducing shipping distances and times. These smaller facilities, often situated within or near urban areas, leverage automation to efficiently fulfill orders for local customers, ensuring rapid delivery within a short timeframe. This approach is particularly effective in densely populated areas where traditional distribution models struggle.

Sustainability Concerns in the Pursuit of Speed

The relentless pursuit of faster shipping also raises important sustainability concerns. The increased volume of deliveries necessitates more fuel consumption and potentially increased emissions. Logistics companies are increasingly focusing on sustainable practices to offset the environmental impact of faster delivery, including exploring electric vehicle fleets, optimizing delivery routes to reduce mileage, and promoting eco-friendly packaging.