Elevating Efficiency Navigating Smart Manufacturing Landscape

Elevating Efficiency: The Dynamics of Smart Manufacturing

Welcome to the era where intelligence meets production, and efficiency takes center stage. In this exploration, we journey through the landscape of smart manufacturing, uncovering the innovations and strategies that propel industries into a new dimension of operational excellence.

Connected Ecosystems: The Essence of Smart Manufacturing

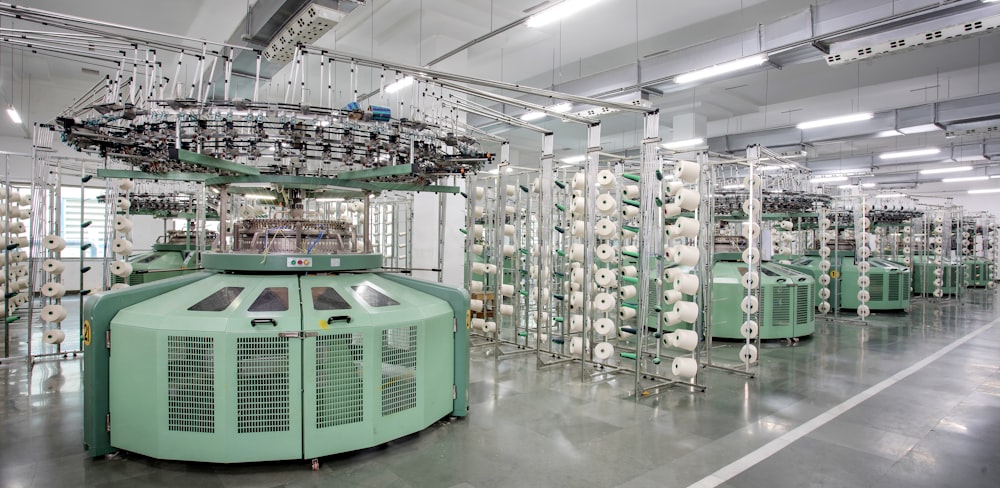

At the core of smart manufacturing lies the concept of connected ecosystems. This involves the seamless integration of machines, sensors, and systems through the Internet of Things (IoT). In a smart manufacturing environment, devices communicate in real time, enabling data-driven decision-making and creating a synchronized production ecosystem.

Data Analytics Driving Insights

One of the pillars of smart manufacturing is the extensive use of data analytics. The copious amounts of data generated by interconnected devices are analyzed to extract meaningful insights. This data-driven approach allows manufacturers to identify patterns, optimize processes, and predict maintenance needs, ultimately enhancing overall operational efficiency.

Predictive Maintenance: Minimizing Downtime

Smart manufacturing introduces predictive maintenance, a game-changer in the industrial landscape. Through continuous monitoring and analysis of machine performance data, manufacturers can predict when equipment is likely to fail and schedule maintenance proactively. This predictive approach minimizes downtime, reduces costs, and extends the lifespan of machinery.

Automation’s Role in Precision

Automation is a key player in the world of smart manufacturing. Robotics and automated systems take on tasks ranging from simple, repetitive actions to complex, precision-oriented processes. This not only enhances accuracy but also allows human workers to focus on more intricate aspects of production, fostering a synergy between man and machine.

Machine Learning: Adapting to Varied Conditions

Smart manufacturing leverages machine learning algorithms to adapt to varied conditions. These algorithms enable machines to learn from data, identify patterns, and make decisions without explicit programming. This adaptability ensures that manufacturing processes can adjust in real time to changes in demand, materials, or other variables.

Customization at Scale: Meeting Diverse Needs

Smart manufacturing excels in customization at scale. The ability to swiftly adapt production processes to meet diverse and changing customer needs is a hallmark of this approach. From personalized consumer goods to specialized industrial components, smart manufacturing ensures that customization doesn’t come at the expense of efficiency.

Cybersecurity in the Digital Realm

With the increased connectivity inherent in smart manufacturing, cybersecurity becomes a paramount concern. Protecting sensitive data, intellectual property, and maintaining the integrity of connected systems are critical aspects of smart manufacturing. Robust cybersecurity measures are implemented to safeguard against potential threats and ensure a secure digital environment.

Human-Machine Collaboration: A Synergistic Approach

Smart manufacturing emphasizes a synergistic approach to human-machine collaboration. While automation and robotics handle repetitive and precision tasks, human workers contribute their creativity, problem-solving skills, and adaptability to the manufacturing process. This collaboration ensures a well-rounded and flexible production environment.

Sustainable Practices: Greening the Manufacturing Landscape

Smart manufacturing integrates sustainability into its core principles. By optimizing processes, reducing waste, and utilizing energy-efficient technologies, smart manufacturing contributes to a greener manufacturing landscape. Sustainability is not just a byproduct but an inherent