Revolutionizing Industries The Modern Industrial Transformation

Revolutionizing Industries: The Modern Industrial Transformation

In the vast tapestry of history, certain epochs stand out as transformative periods that reshaped the very fabric of societies. The Industrial Revolution was one such era, marking a profound shift from agrarian economies to industrialized powerhouses. Let’s unravel the layers of this monumental change and explore its impact on the world.

The Genesis of Transformation: Early Industrialization

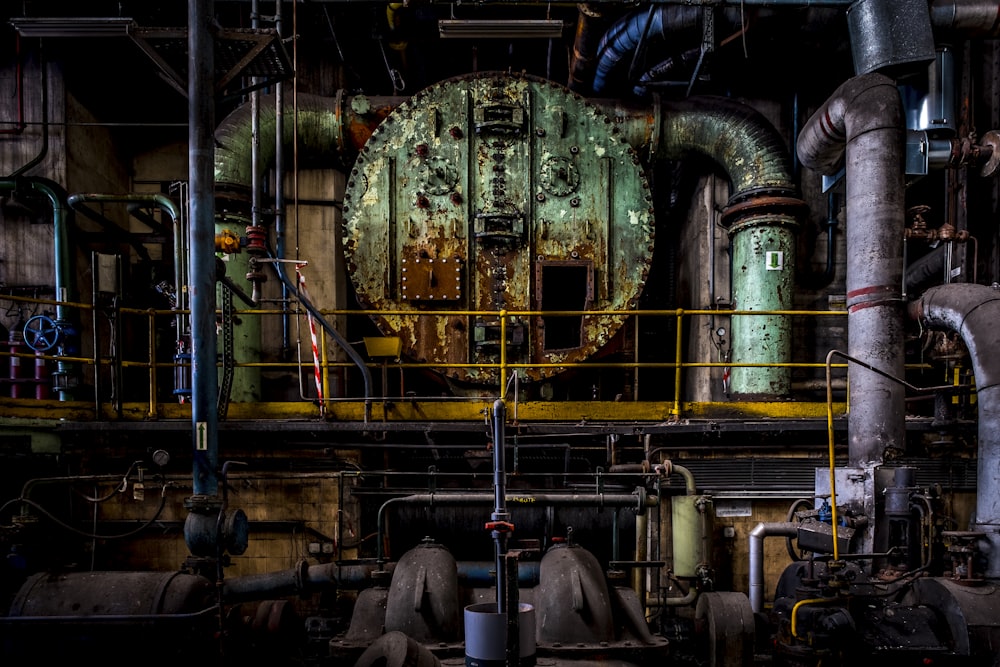

The roots of the Industrial Revolution can be traced back to the 18th century, gaining momentum in Britain before spreading across Europe and eventually reaching other continents. The transition from manual labor to mechanized production was a paradigm shift that saw the emergence of factories and the harnessing of steam power. Industries that once relied on skilled artisans began embracing machinery, forever altering the nature of work.

Machinery’s Might: The Rise of Automation

One of the defining characteristics of the Industrial Revolution was the widespread adoption of machinery. Steam engines, spinning jennies, and power looms revolutionized textile manufacturing, while steam locomotives transformed transportation. The relentless march of innovation introduced unprecedented efficiency, enabling industries to produce goods on a scale previously unimaginable.

Urbanization Unleashed: Migration to Industrial Centers

As factories burgeoned, cities swelled, giving rise to urbanization at an unprecedented pace. Workers flocked to industrial centers, seeking employment in the burgeoning factories. This mass migration reshaped the social and economic landscape, laying the groundwork for the modern urbanized societies we inhabit today.

The Catalyst of Change: Technological Advancements

Technological advancements were the catalysts that propelled the Industrial Revolution forward. Innovations such as the telegraph, the Bessemer process for steel production, and the assembly line method all played pivotal roles in transforming industries. These advancements not only increased efficiency but also interconnected the world in ways previously deemed impossible.

Impacts on Labor: From Hand to Machine

The shift from manual craftsmanship to machine-driven production had profound implications for the labor force. While it ushered in unparalleled productivity, it also led to significant social and economic challenges. The relationship between labor and industry underwent a seismic shift, giving rise to labor movements and the ongoing dialogue about workers’ rights and conditions.

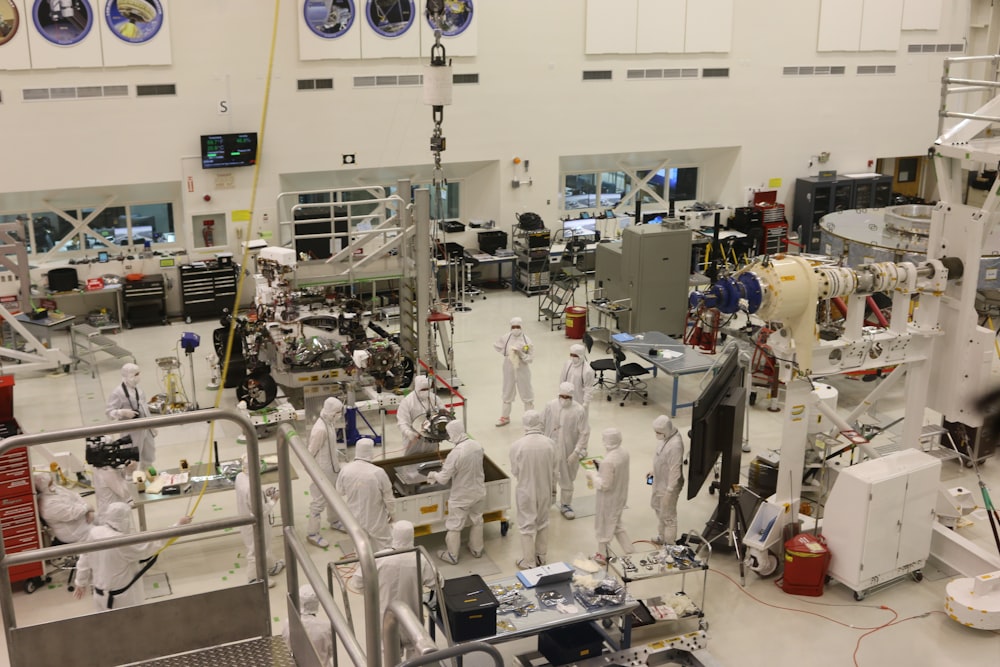

Industrial Revolution 2.0: The Digital Age

Fast forward to the present day, and we find ourselves amid another industrial revolution — one characterized by digital technology. The convergence of data, automation, and artificial intelligence is reshaping industries once again. This modern industrial transformation is not just about machines; it’s about smart systems, interconnected devices, and the relentless pursuit of efficiency.

Explore the ongoing evolution at the heart of the Industrial Revolution. The current landscape is a testament to the enduring spirit of innovation, with industries leveraging cutting-edge technologies to optimize processes and redefine the boundaries of what’s possible.

Sustainable Practices: Balancing Progress with Responsibility

As industries evolve, the importance of sustainability comes to the forefront. The lessons learned from past revolutions emphasize the need to balance progress with responsibility. Modern industrial practices are increasingly focusing on eco-friendly initiatives, renewable energy sources, and ethical manufacturing processes to ensure