Streamlining Production: Cellular Manufacturing

Transforming Production: The Essence of Cellular Manufacturing

Cellular Manufacturing stands as a revolutionary approach to production, reshaping traditional manufacturing methods and unlocking unparalleled efficiency. This strategy, inspired by lean manufacturing principles, introduces a more streamlined and agile way of organizing production processes.

The Concept of Cellular Manufacturing

At its core, Cellular Manufacturing involves organizing production into self-contained units or cells, each dedicated to specific tasks or product lines. Unlike traditional linear production setups, cells are designed to operate independently, fostering flexibility and adaptability in response to changing demands.

Small-Scale Efficiency in Cells

One key feature of Cellular Manufacturing is the emphasis on small-scale, self-sufficient units. These cells often consist of cross-functional teams, bringing together workers with diverse skills needed for the entire production process within that cell. This decentralization promotes teamwork and quick decision-making.

Flexibility and Adaptability

Cellular Manufacturing shines in its ability to adapt swiftly to varying production requirements. As each cell operates independently, it can easily switch from one product line to another, accommodating changes in demand with minimal disruption. This flexibility is a crucial asset in today’s dynamic market.

Lean Principles in Action

Drawing inspiration from lean manufacturing principles, Cellular Manufacturing aims to eliminate waste, reduce lead times, and enhance overall efficiency. By organizing production into cells, companies can identify and eliminate inefficiencies more effectively, optimizing the entire manufacturing process.

Now, if you’re curious to explore how Cellular Manufacturing can revolutionize your production setup, check out Cellular Manufacturing. This resource offers valuable insights and practical tips for implementing Cellular Manufacturing in your operations.

Cross-Functional Collaboration

A fundamental aspect of Cellular Manufacturing is the collaboration of cross-functional teams within each cell. This collaborative structure ensures that team members possess a broad set of skills, allowing them to tackle various tasks within the production process. This not only enhances efficiency but also promotes knowledge sharing.

Reduced Setup Times

Traditional manufacturing setups often suffer from lengthy setup times when transitioning between different products. Cellular Manufacturing addresses this issue by minimizing setup times within each cell. This reduction in changeover times contributes to increased overall productivity and responsiveness to customer demands.

Quality Focus

Cells in Cellular Manufacturing are designed to be self-monitoring and self-controlling. This emphasis on autonomy ensures that each cell is responsible for the quality of its output. By instilling a sense of ownership and accountability within each cell, companies can maintain consistently high product quality.

Employee Empowerment

Cellular Manufacturing empowers frontline workers by involving them in decision-making processes and giving them a stake in the success of their respective cells. This empowerment not only boosts morale but also results in a more engaged and motivated workforce, contributing to overall operational excellence.

Embracing the Future of Manufacturing

In conclusion, Cellular Manufacturing is not just a production strategy; it’s a shift in mindset that embraces the future of manufacturing. By breaking down traditional silos and fostering a more collaborative, agile, and efficient environment, Cellular Manufacturing paves the way for companies to thrive in an ever-evolving market.

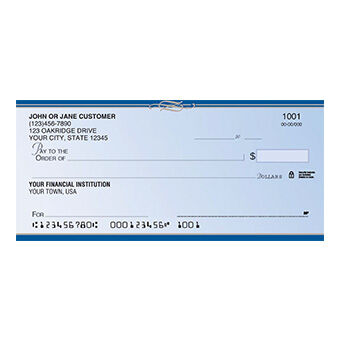

Easily order and re-order private and enterprise checks using Vistaprint’s safe encryption platform. QuickBooks Checks: Spend less time printing checks and more time operating what you are promoting. Whenever you search the Web using Yahoo, content on the Search Results Web page comes from quite a lot of sources. CheckAdvantage, your corporation test skilled on-line.

Easily order and re-order private and enterprise checks using Vistaprint’s safe encryption platform. QuickBooks Checks: Spend less time printing checks and more time operating what you are promoting. Whenever you search the Web using Yahoo, content on the Search Results Web page comes from quite a lot of sources. CheckAdvantage, your corporation test skilled on-line.

Choose from over 3500 test products. Our Regular Enterprise Checking Account is ideal for the rising enterprise with reasonable activity. Yahoo strives to attach you with the products, providers, and businesses you’re on the lookout for. Select your Enterprise Checks by Design. Learn more about Deluxe advertising and marketing services and checks right here.

Choose from over 3500 test products. Our Regular Enterprise Checking Account is ideal for the rising enterprise with reasonable activity. Yahoo strives to attach you with the products, providers, and businesses you’re on the lookout for. Select your Enterprise Checks by Design. Learn more about Deluxe advertising and marketing services and checks right here.

An office cleaning business is relatively easy to set up and beginners can get started for reasonably low startup costs. Other great things about this industry are its sheer size and the fact that it is reasonably insulated from recessions. An office cleaning business can also be run from your home.

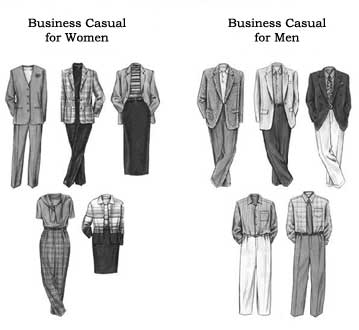

An office cleaning business is relatively easy to set up and beginners can get started for reasonably low startup costs. Other great things about this industry are its sheer size and the fact that it is reasonably insulated from recessions. An office cleaning business can also be run from your home. When selecting a business thought, focus in your strengths and skills. The most probably clients for a private concierge service are high executives who discover themselves at the office by 7 a.m. and are there most nights till 9 p.m., leaving them very little time to do all those things that often have to be completed throughout these very hours.

When selecting a business thought, focus in your strengths and skills. The most probably clients for a private concierge service are high executives who discover themselves at the office by 7 a.m. and are there most nights till 9 p.m., leaving them very little time to do all those things that often have to be completed throughout these very hours.

The bottom line of every efficient business should be how to maximize its profits in a manner that leads to the greatest potential future profitability. As a result, companies are always looking to alter their janitorial programs in such a way to minimize their expenses to boost their bottom line, while maintaining an acceptable level of cleanliness. The following article will help shed light on the dirty business of deciding whether to contract out the cleaning services, or to take care of them in-house.

The bottom line of every efficient business should be how to maximize its profits in a manner that leads to the greatest potential future profitability. As a result, companies are always looking to alter their janitorial programs in such a way to minimize their expenses to boost their bottom line, while maintaining an acceptable level of cleanliness. The following article will help shed light on the dirty business of deciding whether to contract out the cleaning services, or to take care of them in-house.