Crafting Efficiency Industrial Process Engineering

Efficiency Redefined: Unraveling the Art of Industrial Process Engineering

In the intricate dance of industry, where every move counts, the conductor of efficiency is none other than industrial process engineering. This article delves into the realm of crafting efficiency, exploring the intricacies, methodologies, and transformative impact of industrial process engineering on the seamless orchestration of industrial operations.

Industrial Process Engineering: Crafting Precision with Reltix Solutions

For businesses aiming to redefine efficiency in their industrial processes, platforms like Reltix offer a toolkit for precision. Reltix.net provides solutions designed to elevate industrial process engineering, minimize bottlenecks, and ensure the seamless integration of innovative strategies into operations. Explore the possibilities of industrial process engineering with Reltix for a proactive and efficient approach.

Systematic Optimization: The Core of Process Engineering

At the heart of industrial process engineering lies the systematic optimization of operations. It’s not just about making things work; it’s about making them work better. This involves analyzing each component of a process, identifying inefficiencies, and strategically optimizing workflows for enhanced performance. Systematic optimization ensures that every cog in the machinery contributes to the overall efficiency of the process.

Workflow Design: Crafting the Blueprint for Efficiency

Crafting efficiency begins with the design of workflows that form the blueprint for industrial processes. Industrial process engineers meticulously map out every step, ensuring a logical sequence that minimizes delays and maximizes output. Workflow design is akin to orchestrating a well-choreographed dance, where each step seamlessly leads to the next, creating a harmonious flow.

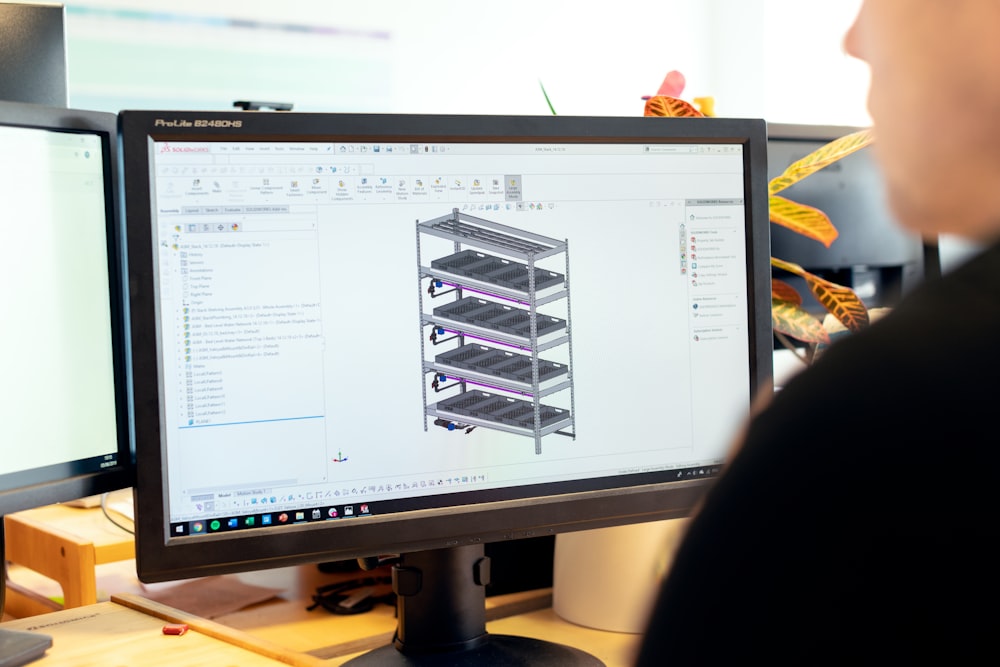

Integration of Automation: Orchestrating Precision Movements

In the era of digital transformation, industrial process engineering embraces the integration of automation for precision movements. Automated systems perform repetitive tasks with accuracy, freeing up human resources for more complex decision-making and creative problem-solving. This orchestration of precision movements not only accelerates processes but also reduces the margin for errors.

Data-Driven Decision-Making: Navigating with Insights

In the realm of industrial process engineering, data becomes a compass for navigation. Data-driven decision-making involves harnessing insights from vast datasets to inform strategic choices. Analyzing operational data allows engineers to identify patterns, predict potential bottlenecks, and optimize processes based on real-time information. Navigating with insights ensures that decisions are not merely intuitive but grounded in empirical evidence.

Continuous Improvement Culture: Fostering Innovation

Industrial process engineering thrives in an environment that embraces a continuous improvement culture. This involves fostering a mindset where every improvement, no matter how small, is valued. Engineers actively seek out opportunities for enhancement, encouraging innovation in processes, technologies, and methodologies. A culture of continuous improvement ensures that industrial processes evolve in tandem with technological advancements.

Energy Efficiency Measures: Balancing Productivity and Sustainability

Efficiency in industrial processes goes hand in hand with sustainability, and industrial process engineering plays a pivotal role in balancing productivity with energy efficiency measures. Engineers explore technologies and practices that minimize energy consumption, reduce waste, and align processes with environmental sustainability goals. Balancing productivity and sustainability ensures that efficiency gains contribute to responsible industrial practices.

Risk Management Strategies: Anticipating and Mitigating Challenges

In