Local Experts: Garage Door Repair Services at Your Doorstep

Local Experts: Garage Door Repair Services at Your Doorstep

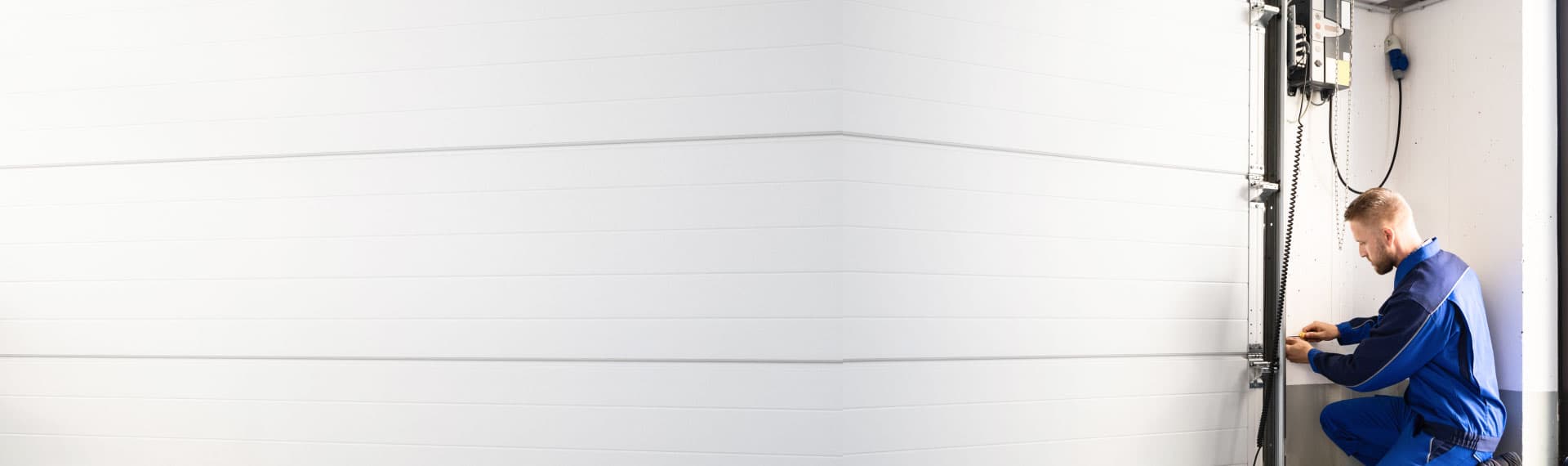

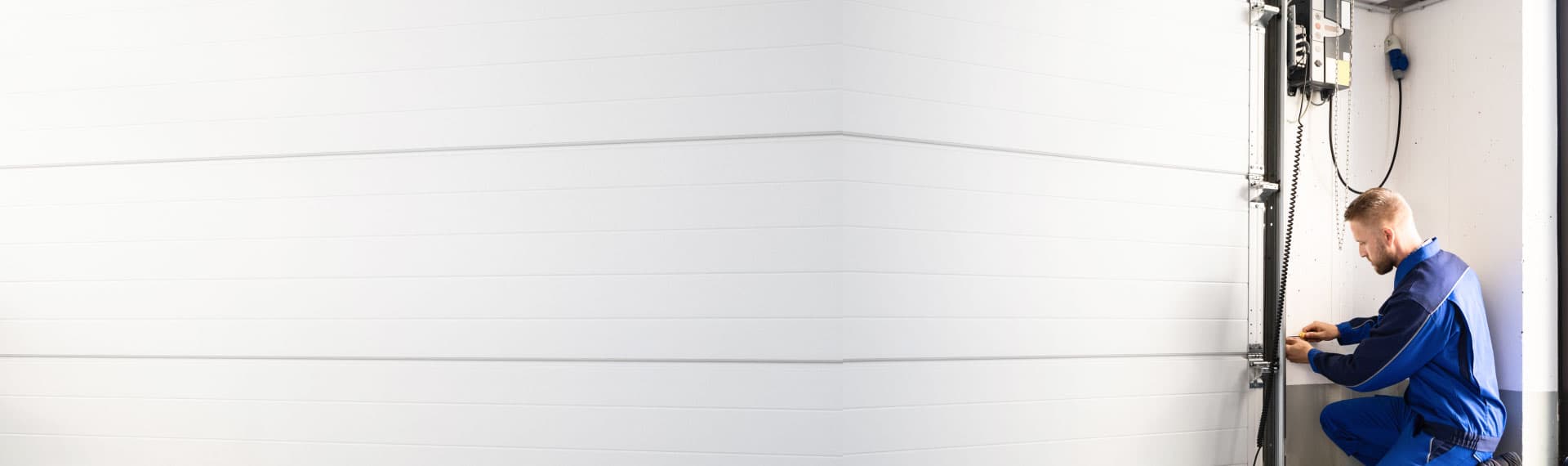

Garage doors play a crucial role in the security and functionality of a home. When issues arise, having access to reliable local garage door repair services is essential. Explore the benefits and considerations when seeking assistance from experts in your neighborhood.

The Importance of Local Expertise

When it comes to garage door repair, local expertise offers distinct advantages. Local repair services understand the specific needs and challenges of your community. They are familiar with the common issues that arise in the local climate and can provide solutions tailored to the region, ensuring a more efficient and effective repair process.

Prompt Response and Quick Assistance

Local garage door repair services prioritize prompt response times. When faced with a malfunctioning garage door, having a local expert who can swiftly assess the situation and provide quick assistance is invaluable. Rapid response times not only address immediate concerns but also contribute to the overall security of your home.

Personalized Service and Attention

Choosing a local repair service often means opting for personalized attention. Local experts take the time to understand your specific requirements and concerns. This personalized approach allows for a more tailored solution, addressing the unique characteristics of your garage door and ensuring that the repair aligns with your expectations.

Faster Turnaround for Repairs

Local garage door repair services typically offer a faster turnaround for repairs. Their proximity allows them to reach your location promptly, minimizing downtime for your garage door. Quick repairs are essential for restoring normalcy to your daily routine and preventing further inconvenience.

Knowledge of Local Regulations and Codes

Local experts are well-versed in local regulations and building codes. This knowledge ensures that any repairs or replacements adhere to the required standards. Compliance with local codes not only guarantees the safety of the repair work but also avoids potential legal issues that may arise from non-compliance.

Community Reputation and Trustworthiness

Local garage door repair services thrive on their community reputation. They are often embedded in the local fabric and prioritize building trust within the community. Seeking services from a reputable local provider ensures that you are entrusting your garage door repair to professionals with a proven track record of reliability and customer satisfaction.

Cost-Effective Solutions

Choosing local experts can be a cost-effective solution. Local businesses tend to have lower overhead costs compared to larger, non-local competitors. As a result, they can offer competitive pricing for their services without compromising on quality. This cost-effectiveness is advantageous for homeowners seeking budget-friendly repair solutions.

Preventive Maintenance and Long-Term Support

Beyond immediate repairs, local garage door experts often offer preventive maintenance services. Regular maintenance is crucial for extending the lifespan of your garage door and preventing potential issues before they escalate. Establishing a long-term relationship with a local service provider ensures ongoing support and maintenance for the optimal performance of your garage door.

Access to Emergency Services

Garage door issues can sometimes occur at inconvenient times. Local garage door repair services often provide emergency services,