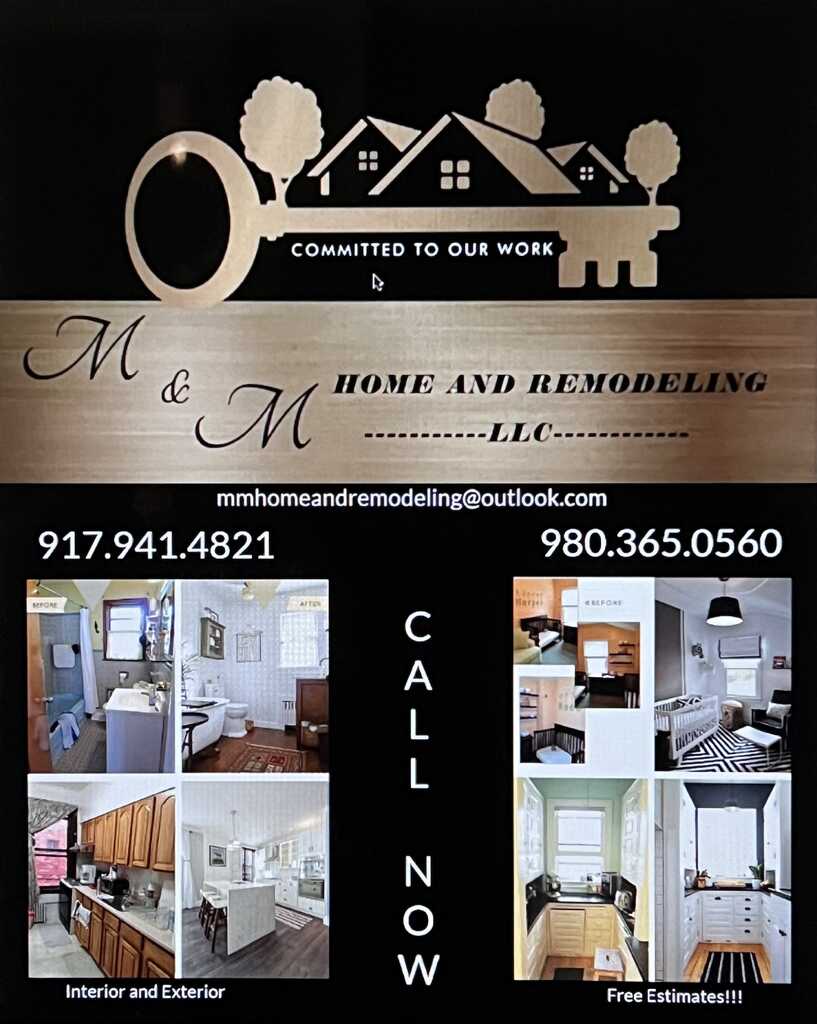

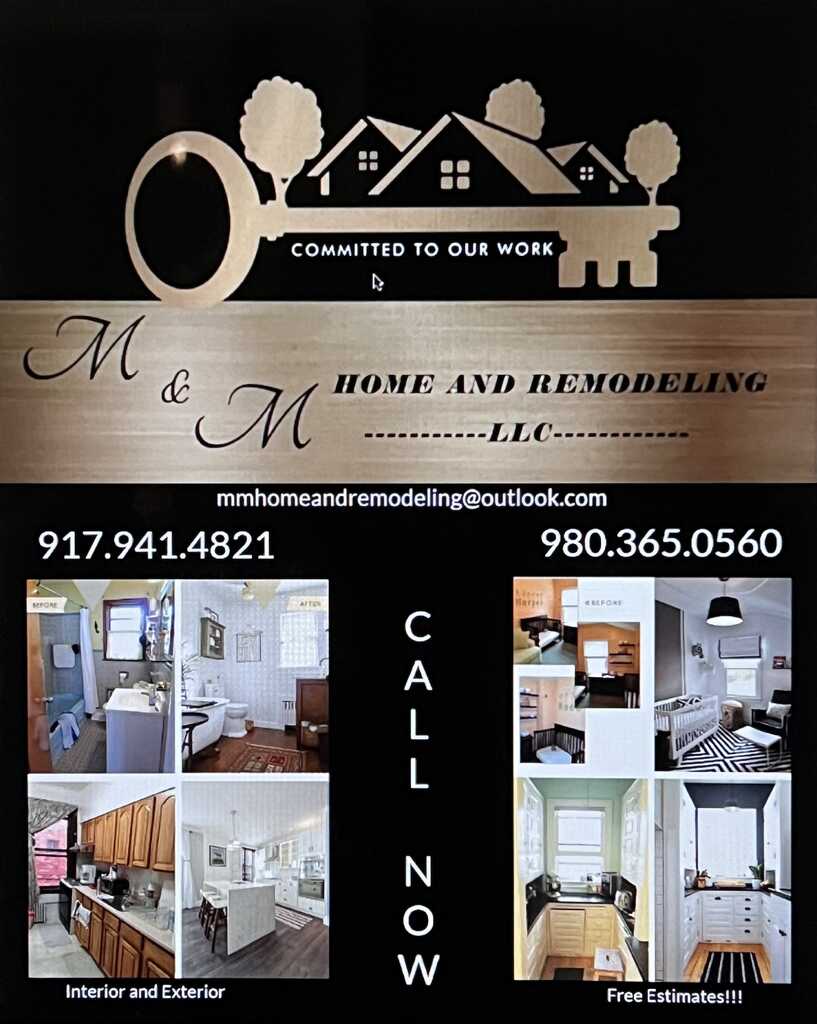

Transform Your Space with M&M Home Remodeling Experts

Unlocking Your Home’s Potential

Expert Guidance for Your Home Renovation Journey

Embarking on a home remodeling project can be both exciting and overwhelming. With M&M Home Remodeling Experts by your side, you can confidently navigate through every step of the process. From initial consultation to project completion, our team of experienced professionals is dedicated to bringing your vision to life while ensuring a smooth and stress-free experience.

Tailored Solutions for Every Space

At M&M Home Remodeling, we understand that every home is unique, and every homeowner has their own set of preferences and requirements. That’s why we offer tailored solutions designed to meet the specific needs of each client. Whether you’re looking to update your kitchen, renovate your bathroom, or transform your entire living space, our team will work closely with you to create a customized plan that reflects your style and enhances your lifestyle.

Craftsmanship and Attention to Detail

When it comes to home remodeling, quality craftsmanship and attention to detail are paramount. At M&M, we take pride in our workmanship, ensuring that every project is completed to the highest standards of excellence. From the selection of materials to the execution of the design, our skilled craftsmen pay meticulous attention to every detail, ensuring a result that exceeds your expectations.

Innovative Design Solutions

With M&M Home Remodeling Experts, you gain access to innovative design solutions that maximize both functionality and aesthetics. Whether you’re working with a small space or a large one, our team will leverage creative design strategies to optimize the layout, improve flow, and enhance usability. From modern and sleek to timeless and traditional, we’ll help you achieve the look and feel you desire for your home.

Transparent Communication and Collaboration

Communication is key to a successful home remodeling project, which is why we prioritize transparency and collaboration every step of the way. From the initial consultation to the final walkthrough, we keep you informed and involved, ensuring that your input is valued and incorporated into the design process. Our goal is to create a collaborative partnership that results in a finished product that reflects your vision and exceeds your expectations.

Efficiency and Timeliness

At M&M Home Remodeling, we understand the importance of timeliness and efficiency when it comes to home renovation projects. That’s why we work diligently to complete your project on time and within budget, without compromising on quality. Our team of professionals is committed to delivering results in a timely manner, so you can start enjoying your newly renovated space as soon as possible.

Customer Satisfaction Guaranteed

Customer satisfaction is our top priority at M&M Home Remodeling Experts. We go above and beyond to ensure that every client is delighted with the final outcome of their project. From the quality of our workmanship to the professionalism of our team, we strive to exceed your expectations at every turn. With M&M, you can trust that your home remodeling project is in good hands.

Embark on Your Home Renovation Journey with M&M

Ready to transform your