Sensing Excellence Smart Sensors Revolutionize Manufacturing

Sensing Excellence: The Evolution of Manufacturing with Smart Sensors

In the intricate dance of modern manufacturing, where precision is paramount, smart sensors emerge as silent but powerful choreographers. These tiny technological marvels are redefining how industries approach production, offering a level of intelligence that goes beyond traditional manufacturing methods.

The Rise of Smart Sensors: More Than Just Detection

Smart sensors represent a quantum leap from conventional sensors. Beyond simple detection, they are equipped with embedded intelligence that enables them to gather, analyze, and communicate data in real-time. This elevates their role from mere observers to active contributors in the manufacturing process.

Real-Time Data for Informed Decisions: Empowering Manufacturers

One of the key benefits of smart sensors is their ability to provide real-time data. This instantaneous flow of information empowers manufacturers to make informed decisions on the fly. Whether it’s monitoring equipment health, optimizing production processes, or ensuring quality control, the live data stream is a game-changer.

Precision in Manufacturing Processes: Enhancing Accuracy

Precision is the hallmark of successful manufacturing, and smart sensors are champions in this arena. From measuring exact dimensions to monitoring temperature variations, these sensors ensure that each step in the production process aligns with the predetermined specifications. The result is unparalleled accuracy in manufacturing.

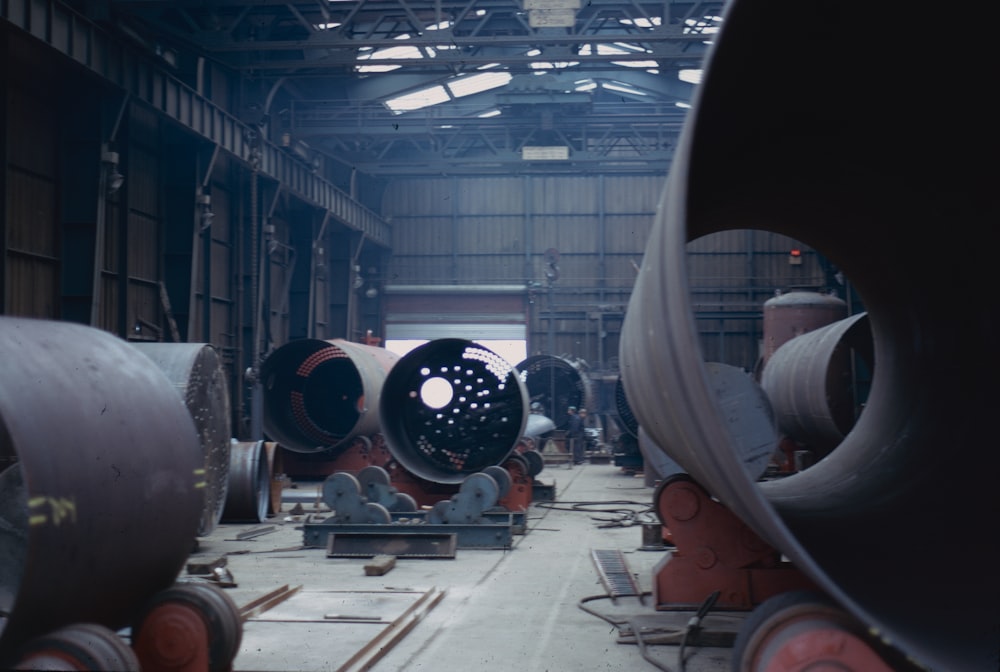

Condition Monitoring: Predicting Maintenance Needs

Smart sensors play a crucial role in predictive maintenance through condition monitoring. By continuously assessing the health of machinery and equipment, these sensors can predict potential issues before they escalate. This proactive approach minimizes downtime, extends the lifespan of equipment, and reduces maintenance costs.

IoT Integration: Creating Connected Factories

Smart sensors are integral to the Internet of Things (IoT) revolution in manufacturing. When embedded in machines and production lines, they transform factories into connected ecosystems. This connectivity allows for seamless communication between devices, fostering a smart and adaptive manufacturing environment.

Quality Control Reinvented: Detecting Defects in Real Time

Traditional quality control methods often involve post-production inspections. Smart sensors, however, revolutionize this approach by detecting defects in real-time during the manufacturing process. This immediate feedback loop enables rapid adjustments, ensuring that only high-quality products reach the final stages.

Supply Chain Optimization: From Production to Distribution

Smart sensors extend their influence beyond the factory floor, reaching into supply chain management. By providing real-time visibility into the movement of goods, these sensors enhance logistics, optimize inventory levels, and contribute to the overall efficiency of the entire supply chain.

Explore Smart Sensors at Smart Sensors in Manufacturing

For those eager to delve into the world of smart sensors in manufacturing, Smart Sensors in Manufacturing offers a gateway to explore solutions and insights. Whether you’re a manufacturing professional seeking to enhance efficiency or simply intrigued by the technological advancements shaping our industries, the platform provides valuable resources.

Cyber-Physical Systems: Bridging the Physical and Digital

Smart sensors play a pivotal role in the creation of cyber-physical systems (CPS). These systems integrate physical processes with digital technologies, creating a symbiotic relationship between the physical world of manufacturing and the digital realm of data analytics and